- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

JLM - proven protection

loading results...

loading results... © JLM Lubricants

© JLM Lubricants  © JLM Lubricants The results of the road test conducted together with HTW Saarland proved the JLM Valve Saver Fluid to be effective, but JLM needed a yet more definitive confirmation

© JLM Lubricants The results of the road test conducted together with HTW Saarland proved the JLM Valve Saver Fluid to be effective, but JLM needed a yet more definitive confirmationFor those of you who are new to the notion of autogas valve wear additives, let's explain who JLM, HTW Saarland and TÜV Rheinland are to start with. JLM is a Dutch company developing and manufacturing various fuel additives, among them the award-winning JLM Valve Saver Fluid (as well as the JLM Valve Saver Kit for applying the fluid into the engine). The HTW Saarland (full name Hochschule für Technik und Wirtschaft des Saarlandes) is a German technical university, while the TÜV is a renowned research and test institute, also based in Germany. Together, the three institutions set out to determine whether valve seat recession was a serious problem and how the Valve Saver Fluid could be used to prevent it.

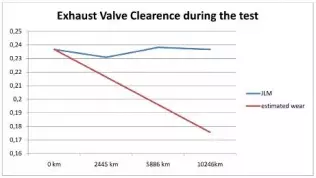

But before any lab-testing involving the TÜV actually happened, JLM had become the first autogas valve wear additive manufacturer to conduct (already in cooperation with HTW Saarland) any kind of testing of their product (literally months after it had been introduced to the market). The first test was a road one covering over 22 thousand km, completed in August 2010. It worked well to convince drivers of the Valve Saver Fluid's effectiveness (unprotected exhaust valves in the test vehicle recessed by approx. 60 µm over 10 thousand km, while protected ones, tested over another 10 thousand km, virtually did not recess at all), but had the disadvantage of not being repetitive enough – traffic and ambient conditions, test driver habits and even fuel quality vary and so do the results. To make them more definitive, JLM moved to a conditioned laboratory environment, which offers more accuracy and reproducibility, thus giving the company hard evidence of the product's worth. The TÜV stamp present on every JLM Valve Saver Fluid's bottle is as hard evidence as it gets.

© JLM LubricantsThe TÜV Rheinland test procedure is no child's play, but the JLM Valve Saver Fluid and Valve Saver Kit endured and performed outstandingly well again

© JLM LubricantsThe TÜV Rheinland test procedure is no child's play, but the JLM Valve Saver Fluid and Valve Saver Kit endured and performed outstandingly well againA 50-hour long test procedure has been developed by TÜV Rheinland and carried out at HTW Saarland's laboratory, with the JLM Valve Saver Fluid being the first product of its kind subject to the test. For the first 25 hours, the test engine (a turbocharged, 4-valves-per-cylinder unit) works without the Valve Saver Fluid so that the extent and rate of valve seat recession can be determined. Part 2 is undertaken with the fluid already in use, testing not only its effectiveness, but also the functioning of the dosing kit. JLM's products passed the rigorous test and were TÜV Rheinland-certified in May 2011, definitely proving effective in preventing valve seat recession. Choosing the JLM Valve Saver Fluid means you are double protected – by the experience stemming from the manufacturer's own road test and by TÜV Rheinland's expertise.

Useful links

You may also find these interesting:

loading results...

loading results...