- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

LPG Direct - directly from Slovenia

loading results...

loading results... © SitecWith Vialle out of the picture (at least temporarily), will Sitec take over as the provider of direct liquid state LPG injection technology? We've got to be patient to see

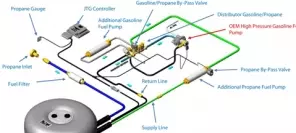

© SitecWith Vialle out of the picture (at least temporarily), will Sitec take over as the provider of direct liquid state LPG injection technology? We've got to be patient to seeThere are two basic ways of converting a DI petrol engine to LPG – applying autogas indirectly, into the intake manifold (with small doses of petrol interjected every now and then to protect the OEM injectors from overheating) or applying autogas directly into the combustion chambers, via the OEM petrol high-pressure pump and injectors. Sitec took the latter option as it offers greater savings and overall simplicity of the solution.

The LPG Direct system features a turbine autogas pump placed inside the LPG tank. Its longevity is estimated at over 160 thousand km. Unlike previous systems of this kind, the Slovenian solution will be able to use standard autogas tanks, although for that to be possible Sitec must complete the process of developing a dedicated multivalve that will support the pump and the entire product. Another crucial component is the pressure regulator unit, whose responsibility it is to switch between LPG and petrol as they enter the common high-pressure fuel injection system.

While Sitec's idea is in no way revolutionary, it has the potential to become a breakthrough. How? If it's priced lower than similar previously available systems (by Prins, BRC and the now-defunct Vialle), it could make the direct liquid state LPG injection idea more popular than it is today (which is primarily caused by high prices of appropriate systems). Which is crucial if autogas is supposed to offer financial advantage over petrol in the future.

You may also find these interesting:

loading results...

loading results...