- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

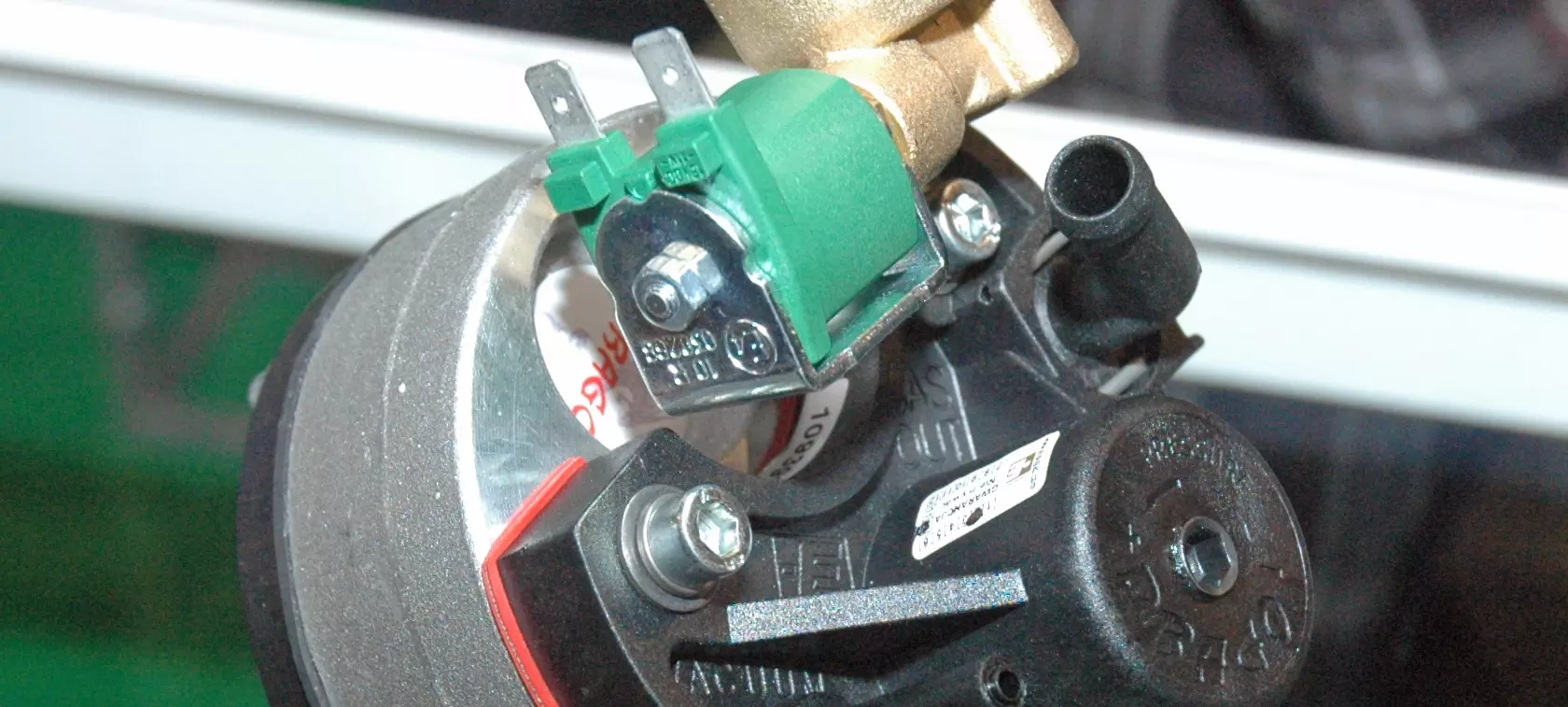

Drago - breathes LPG, not fire

loading results...

loading results...The Drago is a single-stage vapouriser, to be used in 4th generation autogas systems (sequential LPG injection) and based on the already known Fiore Forte model. It is very compact and equipped with rotating connectors (a coolant intake and a gas outlet), bound to be appreciated by installers as they give some freedom in terms of positioning the reducer in the engine bay of a car. Covers on both sides have been made from reinforced plastic, which is supposed to enhance the vapouriser's thermal insulation and prevent heat from dispersing into the surroundings (the reducer warms up quicker and retains temperature for longer).

According to Elpigaz, the Drago maintains stable working pressure across a wide range of engine load conditions thanks to the use of a piston-like pressure reduction element. The vapouriser's differential working pressure is 0,95 bar and maximum output pressure may reach 1,8 bars. Ultimate feed pressure is 25 bars. The main difference in comparison to the Fiore Forte is the Drago's forged aluminium body.

Forging means the structure of the material changes – it becomes denser and free from segregation typical of cast alloy materials, sometimes causing leaks between the water jacket and the LPG vapourising chamber. Additionally, forging saves time as compared to CNC machining. Denser structure has also the advantage of improving heat transfer between coolant liquid and autogas, which in turn enhances the reducer's thermodynamic characteristics and ensures higher output gas temperatures. Elpigaz claims the Drago – thanks to its unique features – cuts LPG consumption by 5-10 per cent when compared to similar reducers offered by other manufacturers. Apparently, this is a dragon worth chasing!

Zobacz stronę producenta:

ElpigazYou may also find these interesting:

loading results...

loading results...