- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Skoda Praktik diesel-gas - dual practicality

- Home page

- Up to date

- Reportages, interviews, road tests

- Road tests

- Skoda Praktik diesel-gas - dual practicality

« Powrót

loading results...

loading results... © gazeo.com

© gazeo.com  Skoda Praktik diesel-gas: unassuming outside, curious inside

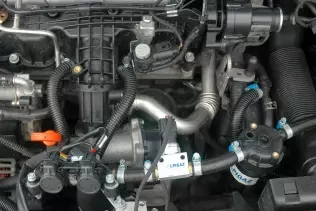

Skoda Praktik diesel-gas: unassuming outside, curious inside  The CNG refueling nozzle is under the bonnet, in the engine bay

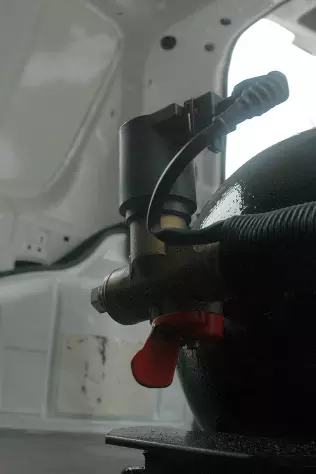

The CNG refueling nozzle is under the bonnet, in the engine bay  And there goes the Tomasetto pressure reducer

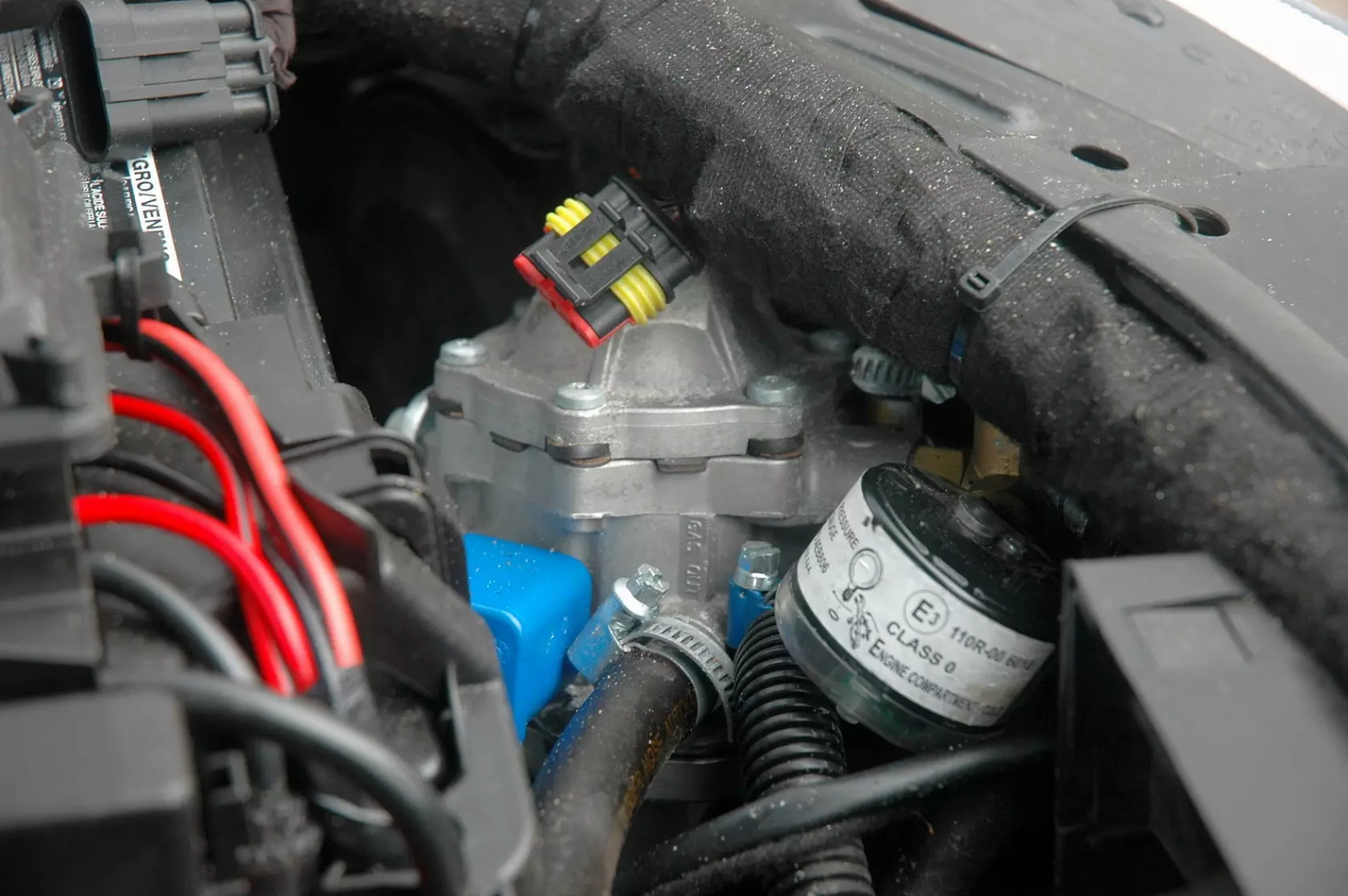

And there goes the Tomasetto pressure reducer  The I-plus injectors

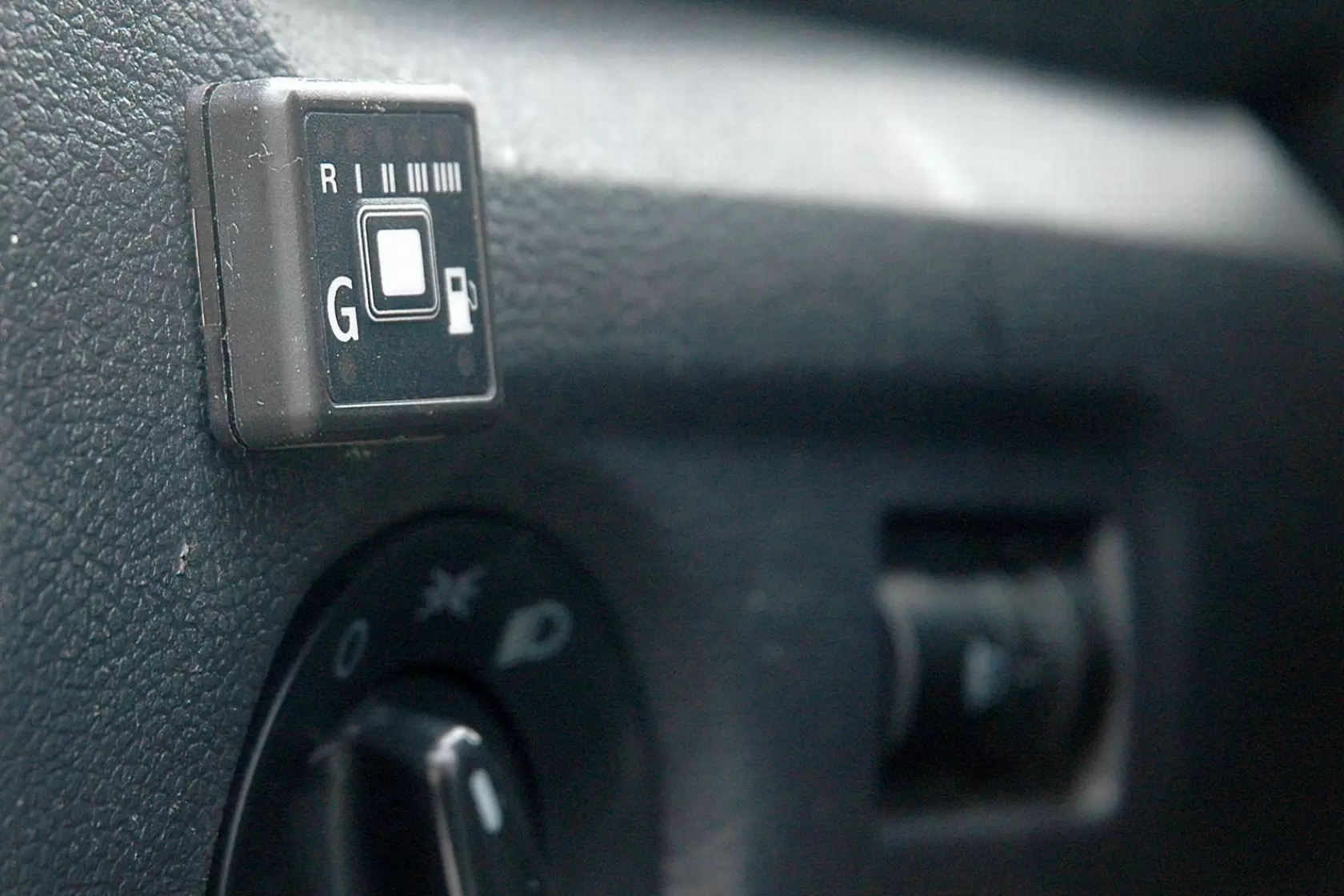

The I-plus injectors  In the cabin, hardly anything has changed - only the switch has been added (on the left)

In the cabin, hardly anything has changed - only the switch has been added (on the left)  The gas switch is right above the lights switch

The gas switch is right above the lights switch  The Praktik enjoys CNG, but does not like biodiesel

The Praktik enjoys CNG, but does not like biodiesel

Having gathered certain data, experience and feedback from the first generation of the DegaMix diesel-gas blending system, Elpigaz now introduces its second iteration. The new one is much more precise, which – in addition to the pressure sensor signal emulation option – makes it possible to remarkably boost gaseous fuel ratio in the overall amount of fuel delivered to combustion chambers. Additionally, by using CNG instead of LPG, gaseous fuel dose may be raised up to 40 percent. With this kind of displacement ratio, converting a diesel to partially run on gas may appeal financially to a broader group of fleet operators than to-date diesel-gas blending systems, generally best-suited for heavy-duty trucks. The DegaMix II, on the other hand, is supposed to appeal to drivers of light-duty delivery vans and passenger cars. The Praktik has been converted as a demonstration vehicle to convince exactly them.

The car

The Roomster's utility counterpart has been equipped with a 66 kW/90 PS 1,6 TDI motor, offering its peak power at 4200 RPM and its peak torque – 230 Nm – as early as at 1500 RPM.

The gas system

The Praktik's gas fuel system has been tuned to boost fuel economy, i. e. to displace as much diesel as possible in favour of cheaper and cleaner compressed natural gas. The system's ECU complies with the 67 R01 and the 110 EEC UN regulations, which means it can be used for controlling both LPG and CNG gas injection systems. In this case a CNG one is used.

The reducer

CNG pressure reduction is the job of the AT12 reducer by Tomasetto. It is a two-stage reducer feeding gas to injectors at constant pressure, regardless of the engine's temporary fuel supply needs. The

pressure can be regulated within the 1-2,5 bar range depending on pressure in the intake manifold. The reducer is efficient enough to supply engines with up to 250 PS of power.

The I-plus injectors

Once the pressure of CNG is reduced, the fuel is filtered and then supplied to two I-plus injectors, injecting natural gas into the intake manifold via diagonally-mounted nozzles. As for the injectors themselves, their construction is based on light plates instead of common pistons. Thanks to this they need very little time to open. They are also supposed to be very little prone to mechanical wear and their longevity is estimated by the manufacturer at 90 thousand km (until first maintenance).

The pressure tank

CNG is stored at 20 MPa in a single steel tank mounted longitudinally in the cargo space, behind the driver's seat. The tank's gross capacity is 50 l, which means it can hold approximately 12 cubic metres of compressed natural gas. It has been fitted with a multivalve comprising the following elements:

- a safety valve rated at 33 MPa pressure;

- a fire valve, allowing gas escape when the tank's temperature reaches 110° C;

- an excessive flow cut-off valve;

- a manually-operated maintenance valve;

- an electromagnetically-operated maintenance valve.

- How the DegaMix II works

Basically, the DegaMix II is a variant of AEB's MP48 DF (Dual Fuel) ECU made specifically for Elpigaz. Apart from controlling gas injectors, it can process the diesel pressure sensor signal and forward it to the engine's original ECU. This way the OEM ECU cuts the diesel dose and makes it possible to inject CNG in its place. Thanks to this operating strategy, relatively high replacement ratios (40 percent and more) can be achieved. However, as compared to its predecessor, the DegaMix II has one flaw – it can only be used to convert common rail-type diesel engines. But since most oil burners use common rail fuel supply strategy these days, this flaw will soon self-eliminate.

Zobacz stronę producenta:

Elpigaz

You may also find these interesting:

loading results...

loading results...