- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

loading results...

loading results... © App Studio

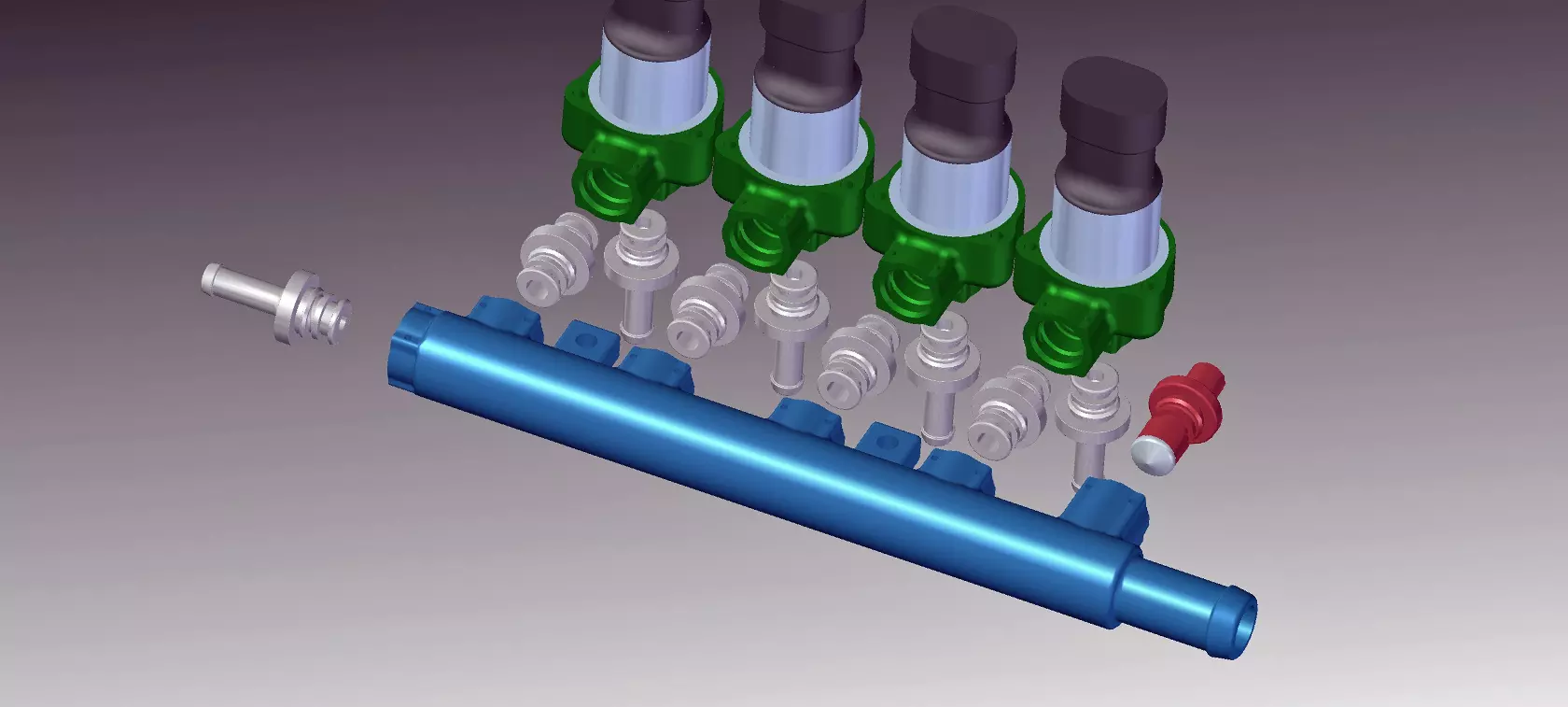

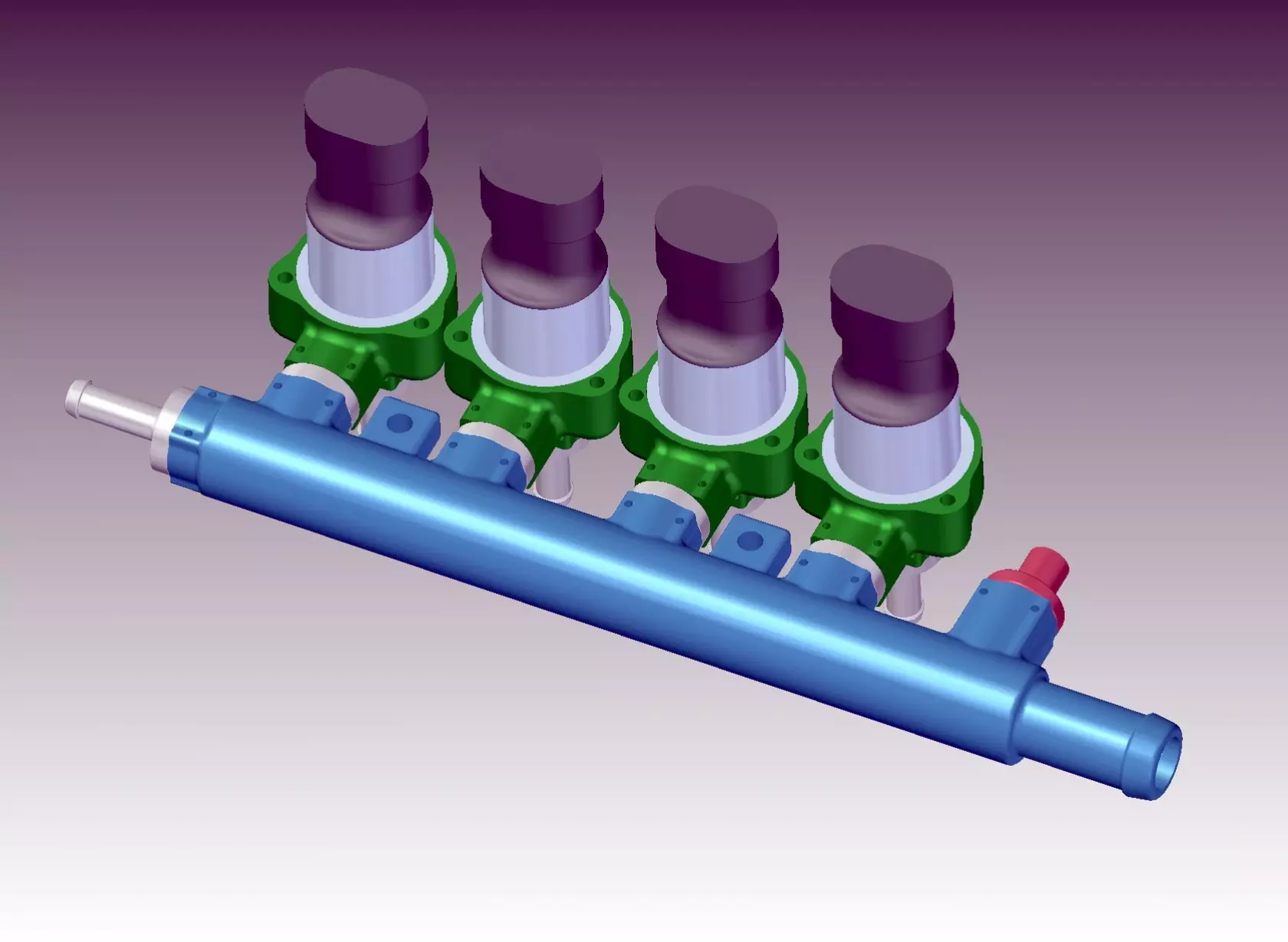

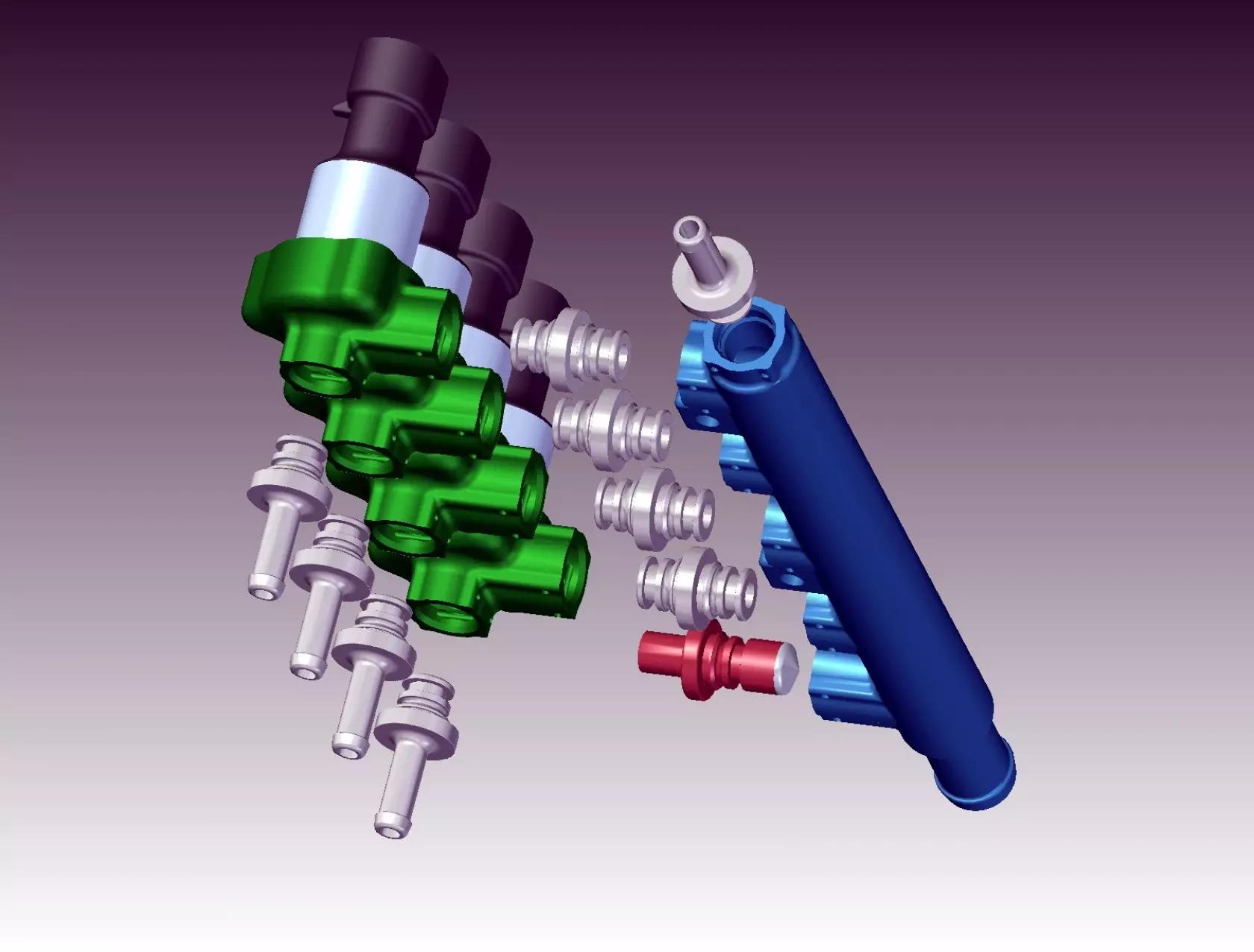

© App Studio  Listwa wtryskowa App Studio wejdzie do oferty firmy w przyszłym roku

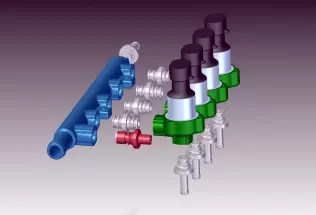

Listwa wtryskowa App Studio wejdzie do oferty firmy w przyszłym roku  Nowe wtryskiwacze Agis będą montowane w listwie za pomocą specjalnych zatrzaskowych łączników

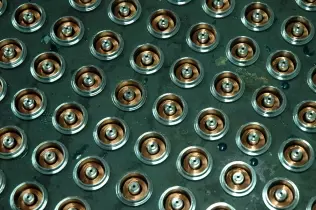

Nowe wtryskiwacze Agis będą montowane w listwie za pomocą specjalnych zatrzaskowych łączników  Masowa produkcja wtryskiwaczy pozwala na obniżenie kostzów produkcji

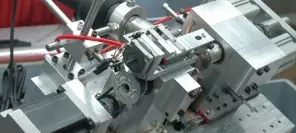

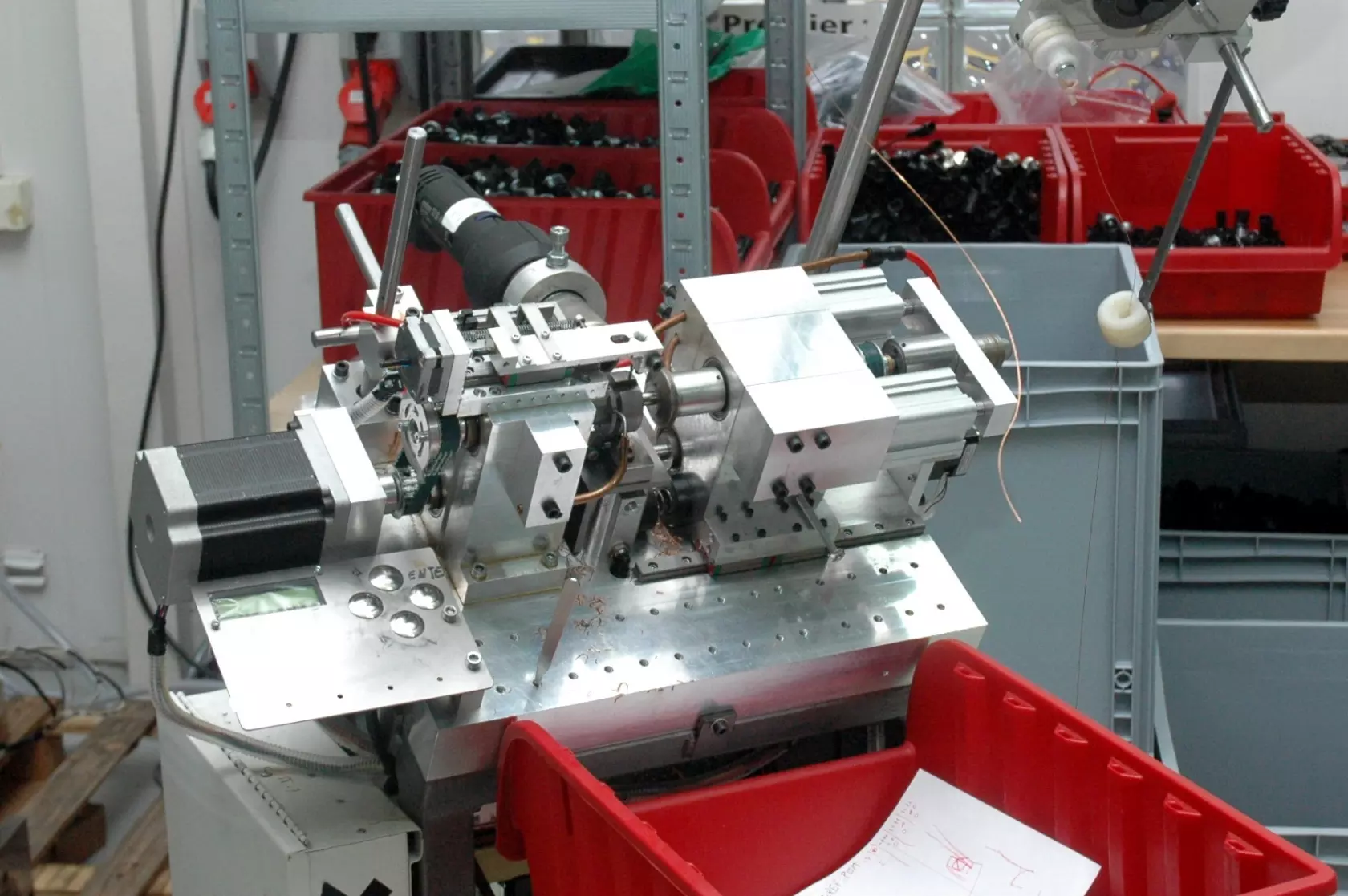

Masowa produkcja wtryskiwaczy pozwala na obniżenie kostzów produkcji  Urządzenie do nawijania cewek wtryskiwaczy jest jednym z przykładów automatyzacji procesów produkcyjnych w firmie App Studio

Urządzenie do nawijania cewek wtryskiwaczy jest jednym z przykładów automatyzacji procesów produkcyjnych w firmie App Studio

Once Apis, now Agis

App Studio's first injector rails, then introduced under the name Apis, were launched in 2008. Apis Solo single injectors soon followed. The new Agis injectors have gone a major redesign aimed at eliminating as many metal elements as possible. This approach enabled the manufacturer to rely more on plastic injection moulding machinery, which makes the production process cheaper (thanks to automatisation) without sacrificing quality or repeatability.

Foundations

When designing the Agis I-12 injectors, emphasis was put on making their operational parameters optimal in low ambient temperatures, particularly at the moment of switching over to gas.

Polish climate proves very demanding for injectors – during the summer they have to work under extremely high temperatures, while in the winter, when temperature falls to -20 degrees Celsius or even below, the first petrol-to-LPG switchover (especially when the switchover temperature threshold is set low) may be not very fluent or even result in stalling the engine.

Tests held during Polish winter proved very successful. Test cars' engines worked steadily after switchover, with no rev speed fluctuations or tendencies towards stalling. This means oily fractions included in LPG, which tend to build up on autogas system components (including injectors) have little influence over performance of the new Agis injectors.

The most important modification

As compared to earlier models of App Studio's injectors, the new Agis has been modified in terms of magnetically-operated opening and closing. The gas flow opening element is pulled by an electromagnet at much higher force, which allows to shorten the opening time and improves low temperature performance.

A plastic body

The injector body has been made of plastic instead of metal, which too influences the Agis' low temperature performance. Thanks to this the I-12 has low thermal inertia – it needs relatively low amount of warmth to warm up, which is crucial for low-temperature switchovers.

Single application

The Agis I-12 injectors are much more compact than their Apis Solo predecessors and can be used for single applications (not necessarily on a rail). This means they can be placed closer to the intake manifold of an engine, which enhances the engine's performance on LPG.

© App StudioMounting the new injectors on rails will require slight modifications. Even so, they will retain the single use option

© App StudioMounting the new injectors on rails will require slight modifications. Even so, they will retain the single use optionFuture (rail application)

Due to large market demand, as soon as in 2013 the Agis I-12 will be prepared for assembling single injectors into rails. Many installers prefer rails since they consider using them as less time-consuming than mounting single injectors in the engine bay of a converted car. The rail will hold up to four injectors and will be equipped with temperature sensor and MAP sensor connectors. If the system to be fit does not require a temperature sensor, its connector may be used for fitting a fifth injector. When converting 2- or 3-cylinder cars, the redundant connectors can be blinded. The rail-ready Agis I-12 will be mildly modified, but will retain the single application option.

To sum up

Addressing the needs of installers and market demands is a very valuable feature in Polish autogas components manufacturers' approach. However, certain balance is also required to decide what is and what is not important and what may help the majority of installers. Adapting the Agis I-12 injectors for use in rails will definitely make things easier for many.

Zobacz stronę producenta:

APPYou may also find these interesting:

loading results...

loading results...