- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Natural gas storage

loading results...

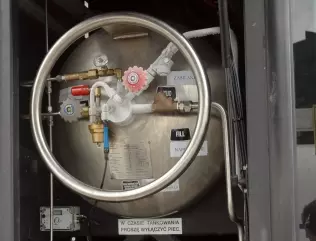

loading results... © bigpaulnoll.comStoring methane in uncompressed form poses something of a challenge. This was the first solution when methane motor fuel was introduced in 1930s, but apparently it's still used today

© bigpaulnoll.comStoring methane in uncompressed form poses something of a challenge. This was the first solution when methane motor fuel was introduced in 1930s, but apparently it's still used todayMethane is the simplest hydrocarbon and, thanks to its basic chemical structure, serves as good and easily combustible fuel, with low percentage of harmful components in exhaust gas.

Due to this fact, traditional natural gas engines usually meet the rigorous EEV standard and the exhaust fumes from gas engines do not contain particular matter or highly carcinogenic aromatic compounds and formaldehydes, the emission of which is not regulated by the applied emission standards.

Another advantage is a considerable reduction of noise made by natural gas engines (2-4 dB), which means the noise is 40% less audible.

The use of natural gas in vehicles dates back to the 1930s – the times of Italian automotive industry’s rapid growth. Introducing natural gas as engine fuel was crucial to the branch’s dynamic development.

Nowadays, natural gas – in many forms, depending on the way it is stored – is widely used, mostly in public transport. Its popularity stems partly from its ecological potential that as well as economical advantages leading to the sector’s constant growth.

Another big advantage of natural gas is the independence from oil monopolists, which – considering the insecure situation in Arabic countries, rich in rock oil deposits – is crucial.

The consumption of 1 kg of petrol (1,3 l) translates into 42-44 MJ of energy. To get that much energy from natural gas, we need approximately 1,35-1,42 cubic meters (under atmospheric pressure). Assuming that an average fuel tank in a passenger car can hold up to 60 liters, storing similar amount of energy in natural gas would require 60 cubic meters of gas. It’s impossible due to space restrictions. Regular natural gas tanks in cars can hold up to 20 cubic meters. To find space even for this limited amount of gas, proper storage techniques had to be applied. The most popular is gas compression.

CNG (Compressed Natural Gas)

Natural gas compression is the most popular method of reducing its volume and is carried out through increasing its pressure to approximately 20-25 MPa. This process increases energy density 200 times. Due to this, it is possible to install relatively small gas tanks in cars that run on CNG. High pressure of CNG means that steel tanks used to store gas are very massive and heavy. However, composite tanks (much more expensive than the steel ones, but definitely lighter) are becoming much more popular.

LNG (Liquefied Natural Gas)

Another method of increasing density of stored natural gas’s energy is its liquefaction. Liquefaction of natural gas is carried out through lowering its temperature to -162° C. Liquefied natural gas takes up 630 less space than natural gas, thus making this method even more effective than compression. But to maintain gas’s liquid state of aggregation, such low temperature must be kept at all times when LNG is stored. This requires the use of special cryogenic tanks and complicated insulation technologies. Unfortunately, a perfect method of thermal isolation does not exist. Stored gas gradually warms up and turns to gaseous state. It increases pressure in the tank which, in turn, causes safety valves to purge gas out of the tank. This means LNG cannot be stored in a tank for too long, because after certain period of time, there won’t be any left in the tank. Drivers who use LNG should remember to refill with only as much LNG as they are able to use in a short period of time. Otherwise, carriers will run the risk of financial losses due to LNG evaporation.

1,338 cubic meters of natural gas will be obtained through full regasification of 1 ton of LNG.

ANG (Adsorbed Natural Gas)

Natural gas adsorption is a technology of storing natural gas in porous materials. One of its main advantages in comparison with CNG is lower gas pressure which allows the use of cheaper tanks. Due to lower pressure of operation, it is also possible to use tanks with shapes other than cylindrical which is crucial in cars and allows more gas to be stored with simultaneous reduction of tank sizes.

Biogas

Biogas is a mix of methane and carbon dioxide, created in the processes of animal and vegetable waste recovery (inside special biogas plants) or at sewage-treatment plants or waste disposal grounds where biogas is now often used as a natural by-product. Recovering methane at such facilities (not allowing it to enter the atmosphere) is essential because this gas has 21 times bigger contribution to the greenhouse effect than carbon dioxide. It means that preventing 1 ton of methane from entering the atmosphere has similar effect as doing the same with 21 tons of CO2. Biogas used in engines is often called biomethane.

Summary

The potential of methane has long been noticed by the automotive industry which is proven by new technologies that make it possible to use it as engine fuel. The biggest obstacle to its popularization is a shortage of properly developed, expensive infrastructure. But recent actions taken by the EU to reduce CO2 emission mean that thanks to economic mechanisms (tax abatements, support projects), car producers, drivers and governments are adapting more positive approach towards natural gas.