- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

SPFI - direct natural gas injection

loading results...

loading results...However, using the SPFI (Spark Plug Fuel Injector) technology makes it possible even when an engine is adapted to gas supply in aftermarket conditions. This technology’s name says a lot, but let’s have some theoretical knowledge first.

Direct fuel injection…

… to a combustion chamber and a cooling effect due to evaporation of fuel that occurs during this process reduces the risk of engine knocking, so the compression ratio can be increased and charging may be applied.

An additional effect of increasing the compression ratio is improvement of charge exchange in the cylinder. Lack of fuel in the intake manifold when fuel is injected directly increases the charging coefficient (a larger amount of fuel can be delivered to the cylinder).

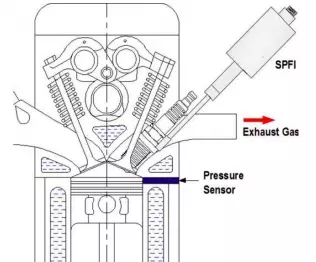

© National University MalaysiaSPFI (Spark Plug Fuel Injector) – a combination of a spark plug and a gas injector

© National University MalaysiaSPFI (Spark Plug Fuel Injector) – a combination of a spark plug and a gas injectorThose factors have a positive impact on the efficiency of the engine, which goes up. This translates to the possibility of reaching higher performance parameters of the motor while fuel consumption is reduced.

Direct injection also increases thermal efficiency of the engine by layering the charge in the combustion chamber. In its various areas the air-fuel mixture has a different lambda factor that conditions the ability to ignite. The mixture of stoichiometric composition is gathered round the spark plug. It’s surrounded by a layer of air that creates a thermal barrier limiting the flow of heat to the walls of the combustion chamber, which results in thermal efficiency boost.

SPFI – Spark Plug Fuel Injector

Converting an engine to direct fuel injection requires modifying or replacing the cylinder head to make room for injectors. In the case of multi-valve-per-cylinder spark ignition engines it’s a very difficult task due to the lack of space in the head.

The SPFI system may help. The conversion requires replacing spark plugs for special SPFI plugs, which are equipped so that they allow delivery of gas fuel directly to combustion chambers. With this solution, engine conversion may be relatively cheap, and the use of direct injection translates to the possibility of achieving parameters not available to engines with fuel injection systems that dose gas fuel to the channels of the intake manifold.

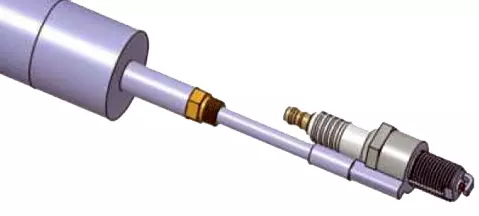

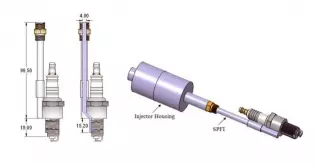

Construction of the SPFI spark plug

The SPFI (Spark Plug Fuel Injector) is a spark plug with a gas supply inlet along it. In the threaded part of the spark plug, it has dimensions of 1 x 2 mm. This inlet has a soldered tube that delivers gas fuel from the injector. The distance between the injector and the mouth of the inlet nozzle in the combustion chamber is around 110 mm. The injector gets gas fuel under appropriate pressure dependent on the pressure in the cylinder.

Like in other systems, the dose is adjusted by variable injection time. The SPFI system was tested in a Ricardo E6 engine (test engine with variable compression ratio used to evaluate the effectiveness of different fuel blends). Tests allowed to compare this type of supply with an optimally calibrated system that injects gas to the inlet. Results show that the SPFI system performs slightly worse compared to systems in which gas is injected to the intake, though its volumetric efficiency is much better. This is a result of space constraints in which the air-gas mixture is created, as well as the time it takes to create it. This translates to poor mixing of fuel and air. In addition, gas is injected from the direction of spark plugs electrodes at the moment of ignition. It means that it’s hard to get a stoichiometric mixture close to the spark plug.

Although combustion of methane injected directly into combustion chambers is faster than when it’s injected to the intake manifold, it’s actually slower in the initial phase. This is due to charge layering.

Studies have shown that the unfolding of the direct injection process is consistent with data available in the literature and relatively easy to control.

Working on some details would certainly improve parameters obtained during the preliminary study on the SPFI system. This system could become the perfect solution for adapting engines to run on CNG.

You may also find these interesting:

loading results...

loading results...