- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Roush Propane Racer - doesn't drag around

loading results...

loading results... © Mustang and Fords

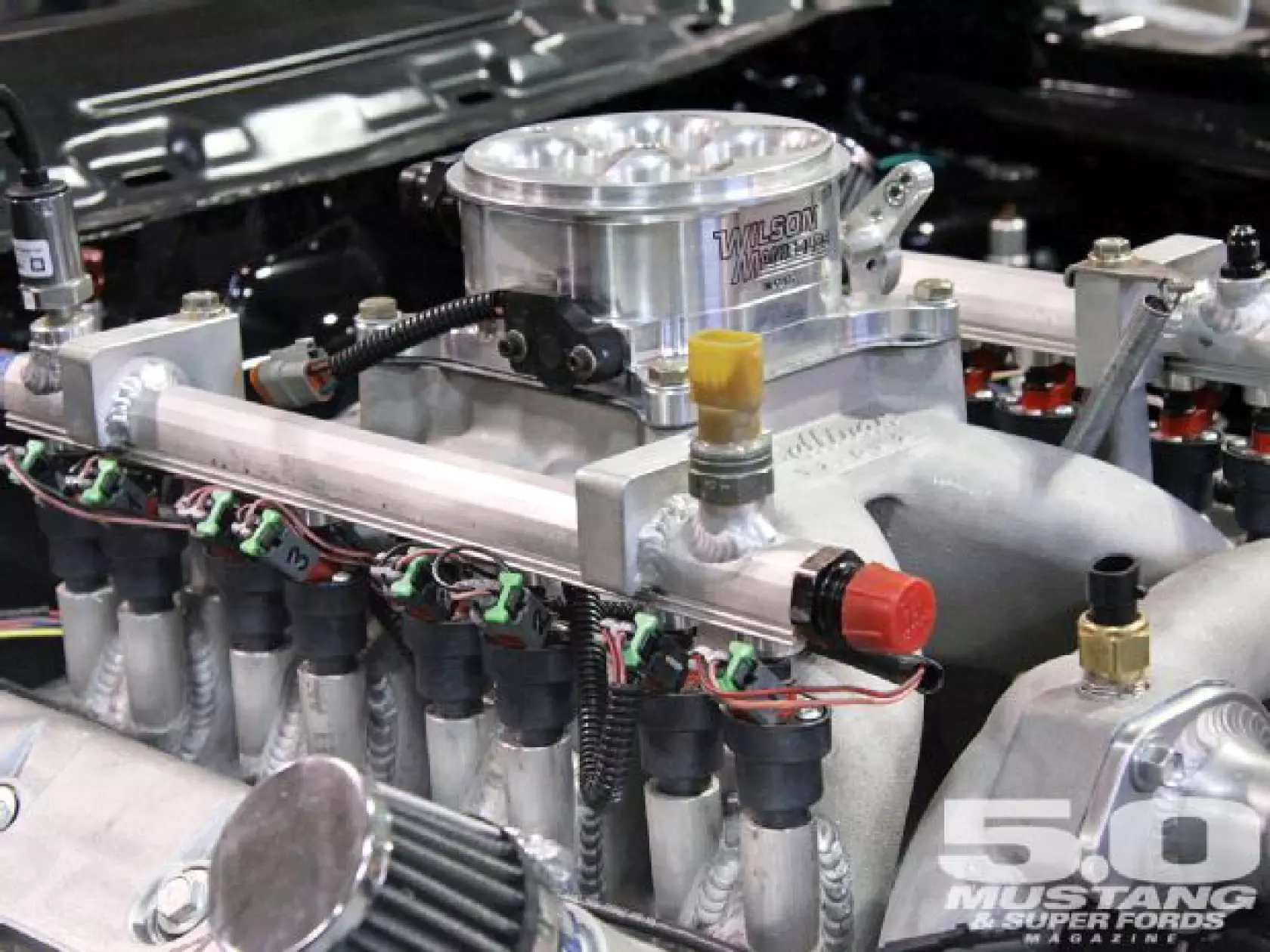

© Mustang and Fords  The Propane Racer's 16 liquid state LPG injectors in all their glory...

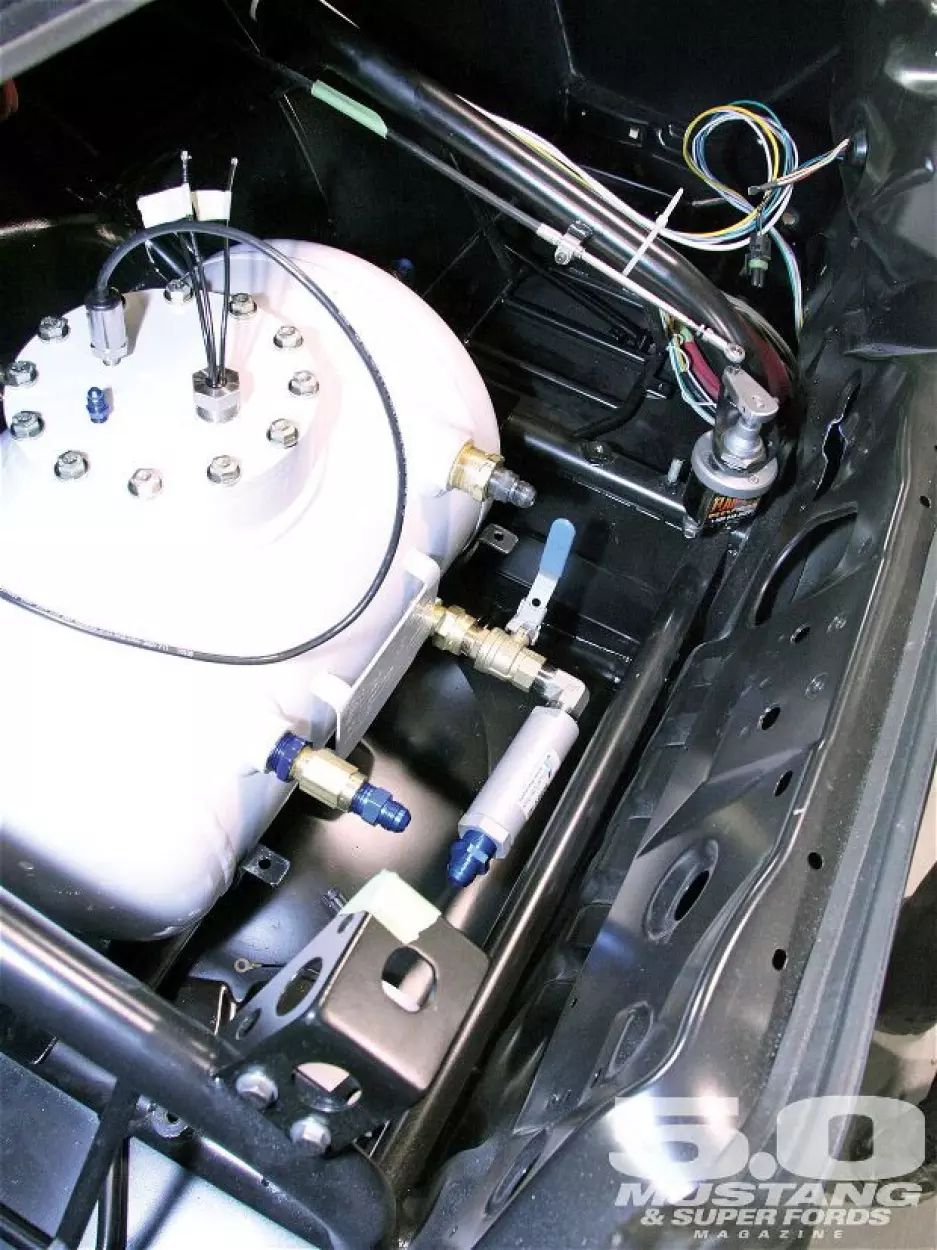

The Propane Racer's 16 liquid state LPG injectors in all their glory...  This is not exactly the kind of autogas tank you get to see everyday

This is not exactly the kind of autogas tank you get to see everyday

© Mustang and FordsIt may look like a Mustang, but underneath the shell it's a whole different story...

© Mustang and FordsIt may look like a Mustang, but underneath the shell it's a whole different story...Unlike many dragsters based on classic 1970's muscle cars, Roush's machine is built upon a modern-day Mustang and so utilises modern-day autogas technology. The engine has been converted with a sequential liquid state LPG injection system, which may be why the power drop between petrol and autogas is only 10 PS – from 635 to 625. However, the car features 16 instead of just 8 LPG injectors. The extra set was installed to enable an overboost. When it was activated, the engine generated 1000 PS in autogas mode!

Inside the LPG tank there is a pump and a pressure regulator, responsible for maintaining a constant pressure of 50 psi (0,34 MPa) above that in the tank. An LPG pressure and temperature sensor located in the fuel rail helps control the pump by compensating flow changes caused by pressure and temperature fluctuations.

As for the tank itself, it's relatively small at 10 gallons (approx. 38 l) of capacity. However, it's big and heavy, because it must withstand internal pressures of up to 300 psi (almost 2 MPa) and meet strict US requirements in terms of safety. It's placed in the boot and protected by a special roll cage. Since LPG is heavier than air, the boot features additional ventilation with a special fan.

The engine has an aluminium block and inside it – wet cylinder sleeves by Darton Sleeves, made of spheroidal cast iron. Inside the sleeves there are Carillo pistons, shaped to provide 12,5 compression ratio. Force unleashed during fuel combustion is transfered through those pistons and connecting rods onto the Kellogg crankshaft. The engine's heads feature hardened valve seats and valves, chosen specifically with LPG in mind. Valves (themselves featuring PAC springs) are opened and closed by means of Comp Cams camshafts, though Jesel tappets and levers. The intake manifold is a Sullivan product, while the throttle body comes from Wilson.

You may also find these interesting:

loading results...

loading results...