- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Chrysler M-body LPG - blast from the past

loading results...

loading results... © Chrysler

© Chrysler American car companies had the nasty habit of excessively using badge engineering. Once a platform and a body had been developed, the outcome was copied across the range of all available brands, with differences limited to logos and trims. It was pretty much the same with the M-body family of Chrysler models, offered in a variety of versions spanning from Plymouth's entry-level to Chrysler's executive models. Some of these, namely the Dodge Diplomat and Plymouth's Gran Fury and Caravelle (the latter in Canada only) variants were offered with factory conversions to LPG. Chrysler and its LeBaron, New Yorker and Fifth Avenue models did not participate in the program.

The autogas systems were the creation of Chrysler's internal team of engineers, both in terms of design and conversion process. All the components were thus covered by the manufacturer's full warranty program, while spare parts were offered by dealers. Comprehensive, computer-assisted crash tests were conducted, as well as extreme climate chamber tests (to simulate harsh conditions in northern Canada). No wonder the M-body series cars quickly became Canada's most popular LPG-powered models on the market.

"The M-bodies” proved popular among fleets in the US and Canada, police and taxi fleets in particular (which, incidentally, can still be seen in old American films). With these customers in mind, certain special versions of the LPG-powered cars were prepared (e. g. power packages for the police). The only engine available was a 318 cubic inch (5,2 l) V8, equipped with hardened valves and valve seats. The converted engine was tested for durability over a distance of 4 mln km before launch, and for the 1986 model year new engine heads were introduced for improved power (150 PS) and torque (353 Nm).

Results of the tests performed were used to program engine ECU's. Ignition characteristics differed depending on ambient temperature and engine temperature, so that combustion conditions were optimal at all times. Furthermore, intake air heaters were eliminated to make air-fuel mixture denser and generate higher torque as a result. Thanks to a number of additional connections in the cooling system, a separate cooling circuit for the high-output Impco E-type reducer was provided. The engine was fed through a special Impco carburetor, based on the petrol original, but calibrated for LPG's characteristics. Mixture composition was constantly monitored to avoid lean mixture engine operation.

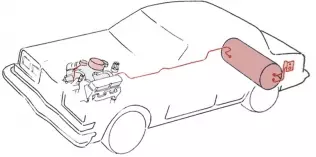

Interestingly, the autogas tank was not mounted inside the trunk. In fact, there were two tanks, fitted under the boot's modified floor, with the spare wheel being moved elsewhere. Autogas-powered M-body series models were monofuel ones – they had no petrol tanks. Dual LPG tanks together were capable of holding 79 l of fuel, offering roughly the same cruising range as on petrol. Safety was an important issue with these cars – each LPG tank had a protective layer of aluminium chemically and mechanically integrated into its outer structure and autogas fuel lines had double steel walls, lead coating and – in places – wire armouring. The filling nozzle was protected by a locked flap.

American cars were never known for their innovations and instead used well-proved technology. However, LPG versions of the M-body Dodges and Plymouths were surprisingly thoroughly designed. Apparently, much attention was given to detail in order to make autogas systems functional and reliable. Drivers enjoyed driving propane-powered Diplomats, Gran Furys and Caravelles, pointing out engine longevity as an important feature, resulting from the fuel's clean burning. Unfortunately, the autogas program was discontinued after 1989, once the M-body cars exited production and today American carmakers have to reinvent the wheel when it comes to LPG systems instead of continuing a tradition they used to have. Pity.

You may also find these interesting:

loading results...

loading results...