- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

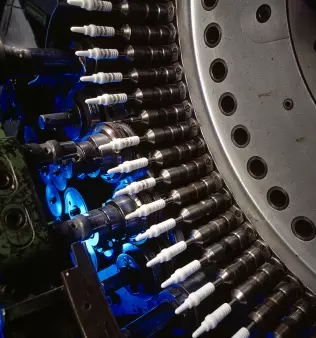

Spark plugs and LPG

loading results...

loading results...So what are these electrodes made of?

Using special materials (those that have lower spark erosion) for electrodes in spark plugs is another way to increase their durability. Various kinds of additives are intended to facilitate ionization of the mixture between electrodes which has a positive effect on lowering breakdown voltage at which spark is created. In the plugs dedicated to LPG fueled engines such solutions are quite common due to difficult conditions in this type of drive units. Precious metals are used: silver, platinum, gold and their alloys with other metals (e.g. palladium). Silver is a very good material from which a central electrode can be made due to its excellent thermal conductivity and resistance to erosion. The electrode made of silver is thinner, which has additional advantages in the form of thinner and longer insulator. At the same thread diameter, the heat chamber is bigger (the space between the insulator and the outer metal part of the spark plug), which causes the plug to reach the self-cleaning temperature faster, and the durability of the electrode is much greater.

Insulator

The thing we pay attention to when we take a closer look at the spark plug is the insulator. Only its outer part is visible. The rest is located in the plug shell, and the tip with the center electrode protrudes into the combustion chamber. The conditions inside the engine require the insulator to be made of ceramics (alumina being the main component) resistant to mechanical (pressure changes) and thermal load, but keeping its insulating properties. The outer part of the insulator is glazed, which prevents the formation of impurities that could absorb moisture and cause uncontrolled discharge between the central electrode and the body. There’s additional protection in the form of grooves on the insulator, extending the path for leakage current. Part of the insulator protruding to the combustion chamber is polished, which reduces the chance that carbon deposits will settle.

Bosch spark plugs

Bosch, the inventor of modern spark plug (Robert Bosch patented the plug in early 1902) manufactures over 350 million plugs each year. These are plugs dedicated to various devices, including gas-powered engines.

Bosch Super plugs are the most numerous group among this type of products. The plugs’ core made of copper causes these plugs to quickly reach the operating temperature and the self-cleaning ability. The copper core is protected by a nickel-chromium alloy against corrosion and spark erosion, which is the consequence of sparking over between the plugs’ electrodes. The range of Bosch Super Plus plugs is characterized by the use of a special yttrium alloy in electrodes. Also the shape of the side electrode (ground electrode) is characteristic in this type of plugs. An electrode with a “pointed” tip was used so a particularly high voltage ignition is not required. Some types of Bosch Super plugs also use nickel-yttrium alloys and platinum electrodes.

© BoschBosch YR 6 LE 02 is a spark plug designed for small engines that follow the downsizing trends (it’s used in Volkswagen up!). By replacing the nut with a cup-shaped connector, this spark plug has an insulator 9 mm longer than in standard plugs. As a result, voltage generated between electrodes can be increased even up to 31 thousand V

© BoschBosch YR 6 LE 02 is a spark plug designed for small engines that follow the downsizing trends (it’s used in Volkswagen up!). By replacing the nut with a cup-shaped connector, this spark plug has an insulator 9 mm longer than in standard plugs. As a result, voltage generated between electrodes can be increased even up to 31 thousand VBosch Super Plus spark plugs quickly reach appropriate operating temperature and are characterized by high operation reliability in the entire time the engine operates, including the start-up. This helps in protecting the engine and the catalytic converter.

Platin-Iridium uses the most expensive of precious metals – platinum – which has the lowest level of heat and electric conduction, and the smallest thermal expansion among all precious metals. It is characterized by high resistance to corrosion which makes Platin-Iridium spark plugs especially durable. These plugs have a copper core and platinum electrodes. Bosch recommends Platin-Iridium spark plugs for gas-fueled engines.

Bosch Super 4 is a type of a spark plug in which air gap spark technology is used. These plugs have four thin ground electrodes and a pointed and silver-plated central electrode.

For engines running continuously at higher speeds, where high reliability of ignition and one hundred percent safety is required, Bosch Silver plugs are used. They are used in sports motorcycles and yachts, as well as snowmobiles.

Trends

Due to systematic expansion of the valves’ sizes, there’s less and less space in combustion chambers for spark plugs. That’s why the trend is to reduce their diameters. There’s also an ongoing research on other methods of ignition in engines – e.g. plasma ignition, in which the plug is replaced by plasma (fully ionized gas), produced in a special generator. As a result, ignition of lean blends is also possible, which can reduce fuel consumption and emissions of harmful exhaust gases.

Researchers from the University of Liverpool had an idea about replacing traditional plugs with laser beam which would reduce fuel consumption and exhaust gas emission.

Summary

As you can see, the spark plug is not a very complicated device, but we must remember that it operates in extreme conditions. During its short life, it must create more than 20 million sparks in a cylinder, in which the difference in pressure between the strokes may be as big as 50 bar, and in temperature of up to 3000° C!

You may also find these interesting:

loading results...

loading results...