- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Oil additives - what do you know about them?

loading results...

loading results...To meet those demands, oil manufacturers commonly use a variety of additives. Currently, almost 20% of the volume of all commercially available types of oil is taken up by additives. The rest (80%) is a mixture of base oil.

Different additives for different oils

Mineral oil (base oil) is a product of nature and its properties are the result of compounds used in its production. Due to this, it is necessary to correct certain characteristics. Some of them are strengthened (e.g. by anti-wear additives strengthening oil film) or weakened (e.g. through antifoam additives).

The situation is a bit different in the case of synthetic oils, which are a product of ethylene synthesis and therefore it’s possible to impart certain characteristics to the base oil during this process. That’s why additives are significantly different in synthetic and mineral oils.

Another difference is the quality of additives. Not only the price goes up with the increase in their quality, but also their durability and the ability to keep the preset parameters. Both the best and the worst oils work similarly at the beginning. But after some time (sometimes it is a remarkably short period of time) the differences are growing bigger.

The durability of additives in popular oils is calculated for mileage of about 20 000 km, so as to ensure proper protection for 15 000 km, which is standard mileage expected by car manufacturers. With LongLife oils, this period may be extended to 60 000 kilometers in passenger cars and even 150 000 km in the case of trucks.

Most common additives used in engine oils

1. Anti-wear – additives that strengthen and thicken oil film. They react with metals to create surface with lower friction coefficient, reducing engine wear.

Excess – increases the internal resistance of oil, which is associated with an increase in the amount of energy absorbed by oil.

Deficiency – increases wear of cooperating components.

2. Viscosity modifiers – including depressants and thickeners. These are polymers which, along with changing temperature, stabilize oil’s viscosity and performance parameters.

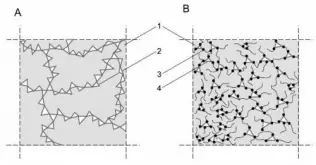

© Total How depressants work at low temperatures: A –base oil without depressant, B – base oil with depressant; 1 – base oil, 2 – paraffin crystals, 3 – depressant’s molecule, 4 – paraffin’s crystal nucleus

© Total How depressants work at low temperatures: A –base oil without depressant, B – base oil with depressant; 1 – base oil, 2 – paraffin crystals, 3 – depressant’s molecule, 4 – paraffin’s crystal nucleusDepressants (also known as pour point depressants) – additives that reduce oil crystallization temperature and therefore also oil pumpability temperature, which results in reducing the time that passes between starting the engine and proper lubrication of all parts of the engine. These additives are activated at low temperatures.

Excess – causes loss of oil viscosity and a decrease in the thickness and durability of oil film. As a result, it causes increased engine wear.

Deficiency – contributes to a rapid increase in viscosity at low temperatures, increase of pumping resistance, extension of time between starting the engine and its proper lubrication, and increased engine wear during “cold starts”.

Thickeners – the opposite of depressants. These additives are activated at high temperatures and their task is to stop the process of decreasing oil’s viscosity when the temperature goes up. This allows oil at high temperatures to create durable and thick oil film that will properly protect your engine.

Excess – causes an increase in viscosity at high temperatures, higher energy consumption of oil and worse flow in oil ways.

Deficiency – at high temperatures it may lead to the loss of viscosity and oil film thickness, accelerating engine wear.

3. Dispersants – additives particularly important for diesel engines. Their job is to neutralize the negative effect of particulates or soot that accumulates at the bottom of the oil sump and in oil ways. In the long term it leads to reduction of oil ways’ diameters and deterioration of lubrication. Another negative thing that comes with soot is that particles accumulate and form clusters. This causes polishing of cylinder linen and removing honing layer. At the same time the wear of shafts and bearings increases. To prevent such situations, dispersants are added to oil and they prevent the accumulation of soot by keeping it in the form of suspended matter in oil. Dispersants also break soot into small particles that do not polish surfaces and do not increase their wear. Thanks to them, during oil replacement all soot is removed from the engine and does not accumulate.

Excess – no negative effects

Deficiency – causes clogging of pre-filters (the so called strainers) and oil filters. It also makes soot accumulate at the bottom of the oil sump and in oil ways. This results in reduction of oil ways’ diameters and the amount of oil supplied to the friction pair.

4. Friction modifiers – perform similar tasks as anti-wear additives but they don’t have to react with metals. These may be compounds which – due to their physical properties – reduce the friction factor.

Excess – In motorcycle engines with wet clutch they cause clutch slippage and burning of clutch plates.

Deficiency – causes greater wear of mating components.

5. Anti-foam additives – added to the base oil in order to reduce foaming. These additives reduce surface tension, causing “popping” of air bubbles. As a result, we’re sure that oil – not foam from oil – will be transported to the oil main.

Excess – doesn’t cause any side effects.

Deficiency – causes foaming of oil, significantly reducing the efficiency of the oil pump and thus the deterioration of lubrication in the engine and, consequently, engine wear or seizure.

6. Demulsifiers – these additives are designed to enable rapid evaporation of water from oil if oil warms up. Most of the time they enable emission of water vapor above 70° C.

© CastrolThanks to additives, engine oils are able to meet various – and often conflicting – requirements

© CastrolThanks to additives, engine oils are able to meet various – and often conflicting – requirementsExcess – reduces the ability to absorb water vapor at low temperatures.

Deficiency – causes too slow evaporation of water from oil, which may result in the accumulation of water, changes in oil’s viscosity and physicochemical properties.

7. Additives that increase adhesion – these additives are designed to extend the time it takes for the oil film to run off of cooperating mechanisms. They have to provide lubrication for the time after the engine is started until a fresh portion of oil that provides lubrication is delivered.

Excess – increase in energy consumption of oil, higher pumping resistance.

Deficiency – oil film runs off faster after the engine is stopped, which leads to increased wear after it’s started again.

8. Dyes – additives used only to differentiate products. Their presence and amount is not related to working conditions of oil. Fatty dyes are used with oils because they are readily soluble in oils, being insoluble in water.

loading results...

loading results...