- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

LNG shuttle Megastar - the star of stars

loading results...

loading results... © gazeo.com

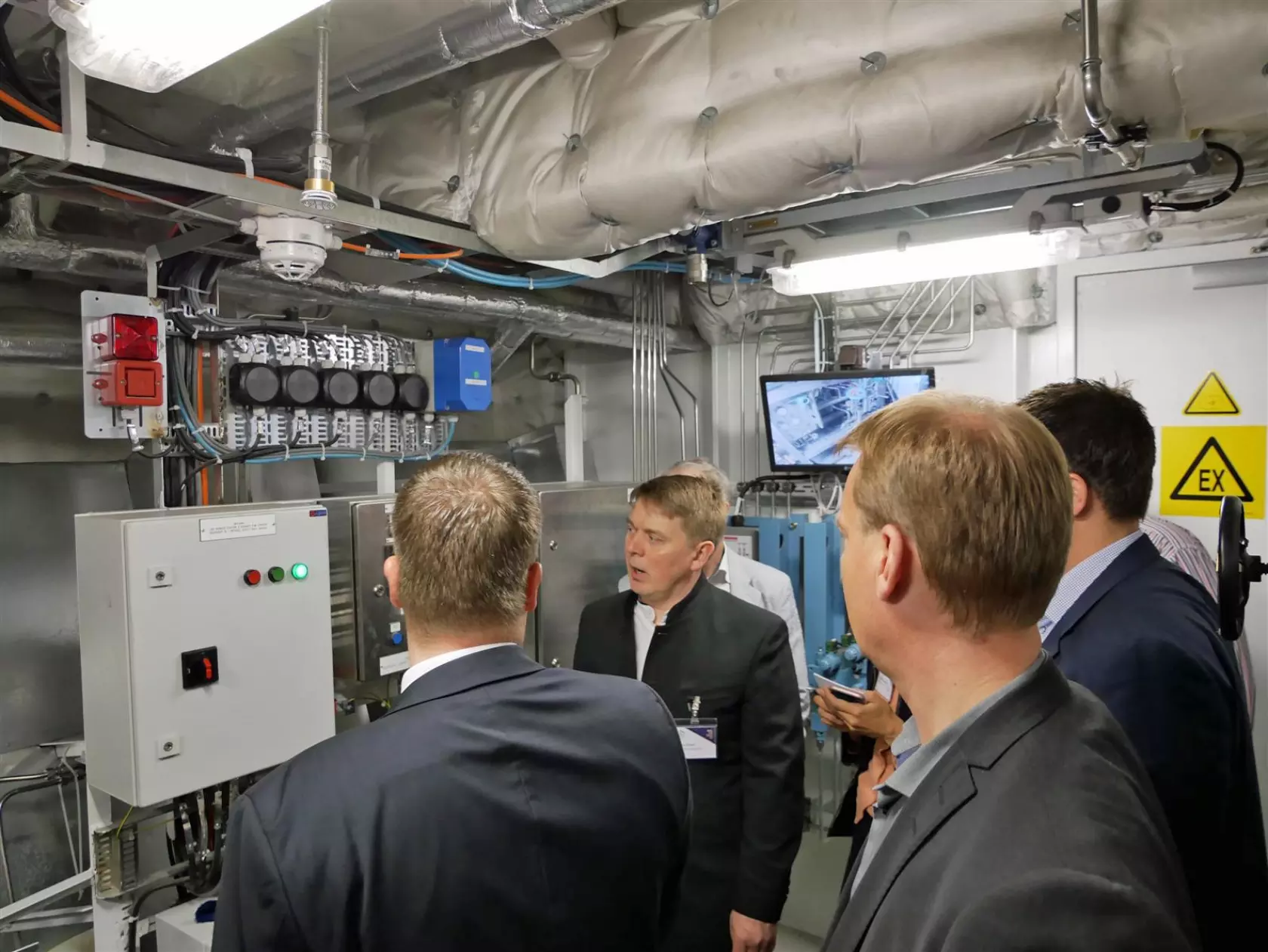

© gazeo.com  This is where the bunkering system is controlled from

This is where the bunkering system is controlled from  The engine room control panel is a small office

The engine room control panel is a small office  The tanks are well insulated, but you can't fool physics - it's considerably cooler in the tank rooms than anywhere else onboard

The tanks are well insulated, but you can't fool physics - it's considerably cooler in the tank rooms than anywhere else onboard  The lens of our camera couldn't capture more than this portion of the shuttle at once

The lens of our camera couldn't capture more than this portion of the shuttle at once  The Megastar is like a floating tower block, as evidenced by the view from the conference room

The Megastar is like a floating tower block, as evidenced by the view from the conference room

It's not accurate to speak of switching from diesel to LNG in this case – the Megastar has been running on liquefied natural gas since day one, i.e. since early 2017 when it was launched to travel regularly between Tallinn (Estonia) and Helsinki (Finland). In fact, the vessel's engines are diesel-fueled by nature and won't work entirely without the oily fuel (it's required in order to initiate compression combustion), but Wärtsilä engineers managed to reduce the diesel dose to just 1% of all fuel used. However, in emergency situations it can be used as primary source of propulsion. But we'll come to that later.

For now, let's focus on the shuttle's technical parameters. As expected, everything about the ship is truly "mega", incluing its physical dimensions. At 212 m long and 30 m wide the Megastar is more than respectable-looking, so if you see it sailing, steer clear of its way. Before we move on to the combustion engines, let us just tell you they don't actually move the propellers that make the giant move, they only generate energy for electric traction motors. Each of the latter has 20,3 MW (27600 PS) of power. LNG to fuel the combustion units is stored in two cryogenic tanks (one per side), 300 m3 each. Combined, that's 600 thousand litres of liquefied methane, cooled to -162° C. Quite a bit, would you agree?

More fuels mean more safety procedures and more stringent ones, too. Here's an example: access to the engine room is only possible through an airlock with gas-tight doors on either side. To open the inside door, you need to wait for the outside one to shut, otherwise there's a safety breach and LNG flow is automatically and immediately cut off, causing the engines to switch over to diesel fuel. The 2000 passengers onboard will never notice, because it happens instantly and seamlessly, but the operator of the Megastar will definitely see the difference on the refueling and engine maintenance bill, so the rules are obeyed. Diesel oil is also an emergency fuel, which can be used in case of an LNG system failure. It hasn't happened to date, hopefully it never will.

© gazeo.comThe bunkering system occupies quite a lot of space, but luckily space is abundant in this case

© gazeo.comThe bunkering system occupies quite a lot of space, but luckily space is abundant in this caseGaseous fuel for the Megastar comes from the Pori terminal in Finland and from Pskov, Russia. From these two locations LNG is transported by cryogenic tanker trucks to the port in Helsinki and bunkering is executed straight from those trucks parked on the pier, with the use of robotised arms connecting fuel hoses to refueling valves on either side of the ship. Bunkering rate is 120 m3/h (from two tankers simultaneously). A 500 m3 permanent tank on the pier, refilled whenever convenient, is also considered by Tallink, the Megastar's operator, which would help make fuel supply more flexible and bunkering more independent from tanker trucks' availability. This would allow to bunker the shuttle once in 3-4 days (as opposed to every day today, with only one hour available during the ship's stop in Helsinki) Ultimately, a bunkering vessel may be used, but for now it's nothing but an idea for the future.

The Wärtsilä engines have their requirements as far as fuel quality is concerned. For example, for them to run efficiently, the methane number of LNG applied to their combustion chambers must not drop below 80. Also, contamination is very much unwelcome, particularly propane, buthane, oily hydrocarbon fractions and carbon dioxide, which can clog the filter and hamper the bunkering process. Not to mention affecting engine performance, causing e.g. knocking and eventually switching over to diesel mode.

© gazeo.comUsing combustion engines for power generation rather than actually propelling the ship makes it possible to run the units under stable, optimal load

© gazeo.comUsing combustion engines for power generation rather than actually propelling the ship makes it possible to run the units under stable, optimal loadLNG is vapourised from liquid to gas in a heat exchanger using the engines' waste cooling water. Methane tanks on their part are well insulated (with a combination of vacuum and perlite powder) to prevent premature vapourisation of LNG, which would result in fuel losses (if LNG vapourises in the tanks, it is vented out to avoid excessive pressure rise). The tanks are bunded, with insulation between the outer and the inner walls, made of stainless steel. Tanks of this kind have their limitations in terms of capacity, but vacuum and perlite can be used with capacities up to 1000 m3, so the Megastar's units are far from exceeding the limit. Besides, compared to polyurethane-insulated tanks, the vacuum-perlite ones offer higher storage pressures and require less frequent technical inspections.

The Megastar is a floating feat of modern engineering. It's cutting-edge, comfortable, environmentally friendly and more economical to run. If LNG infrastructure and bunkering technology around the world develops as expected and projected today, surely more such vessels will appear – not just on the Baltic, but also other seas and oceans. In fact, replacing diesel with liquefied methane as marine fuel should matter to us all, so let's keep our fingers crossed for widespread adoption of LNG.

You may also find these interesting:

loading results...

loading results...