- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Scania G340 LNG - boosted range

- Home page

- Up to date

- Reportages, interviews, road tests

- Road tests

- Scania G340 LNG - boosted range

« Powrót

loading results...

loading results... © gazeo.com

© gazeo.com  The engine's parameters proved enough to move 12 t of load. We're sure another 10 t wouldn't affect performance too much

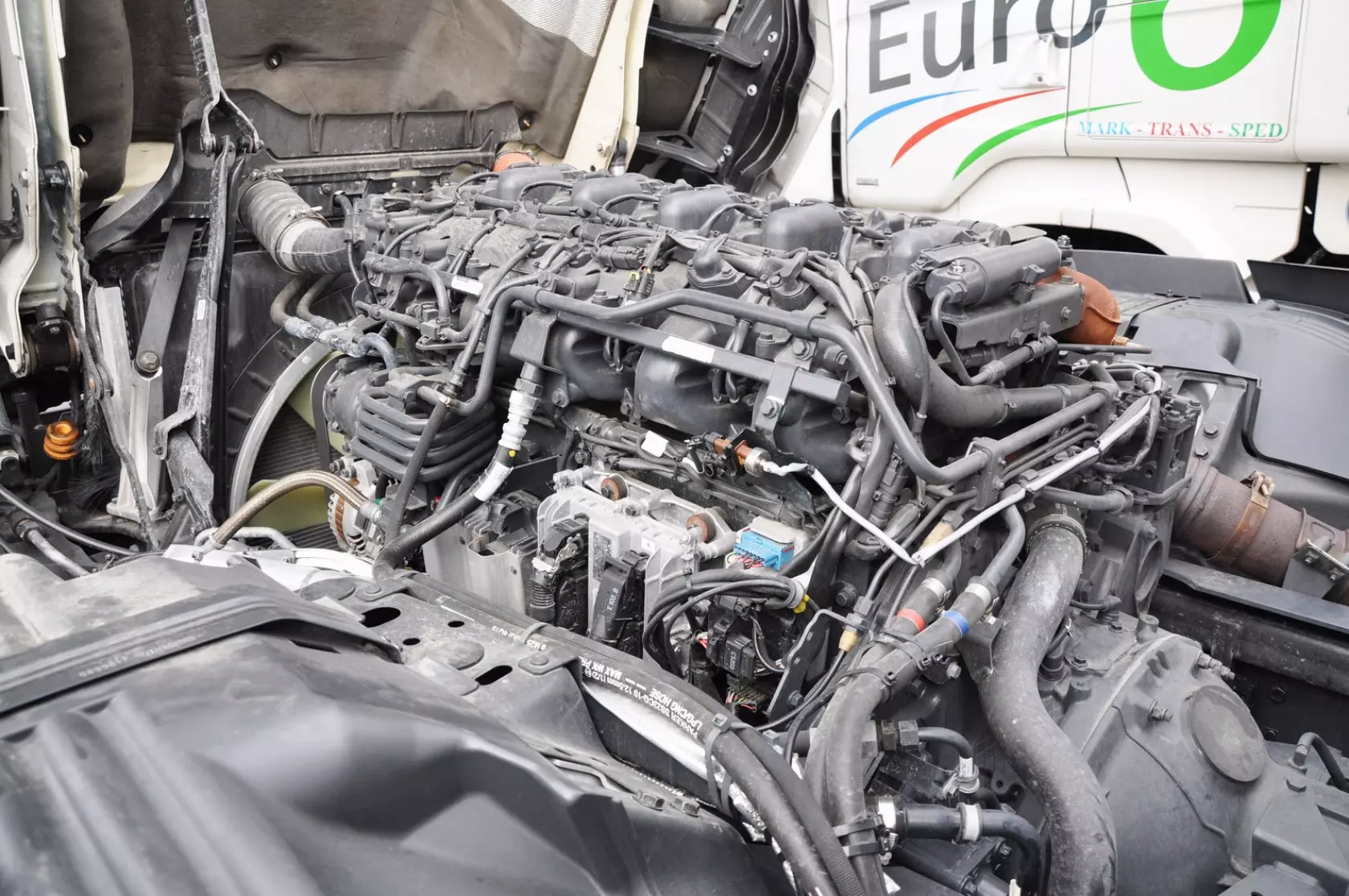

The engine's parameters proved enough to move 12 t of load. We're sure another 10 t wouldn't affect performance too much  Meet the OC09 102 engine in all its glory. Notice the LNG system's ECU

Meet the OC09 102 engine in all its glory. Notice the LNG system's ECU  The Tescom reducer reduces fuel pressure from 16 to 7,3 bar. Once methane is filtered in the Parker Racor filter, it is fed into the engine. Notice the electrovalve, which cuts off fuel flow on the low-pressure side when the engine is switched off, but allows the engine to use up the fuel still present in the hoses

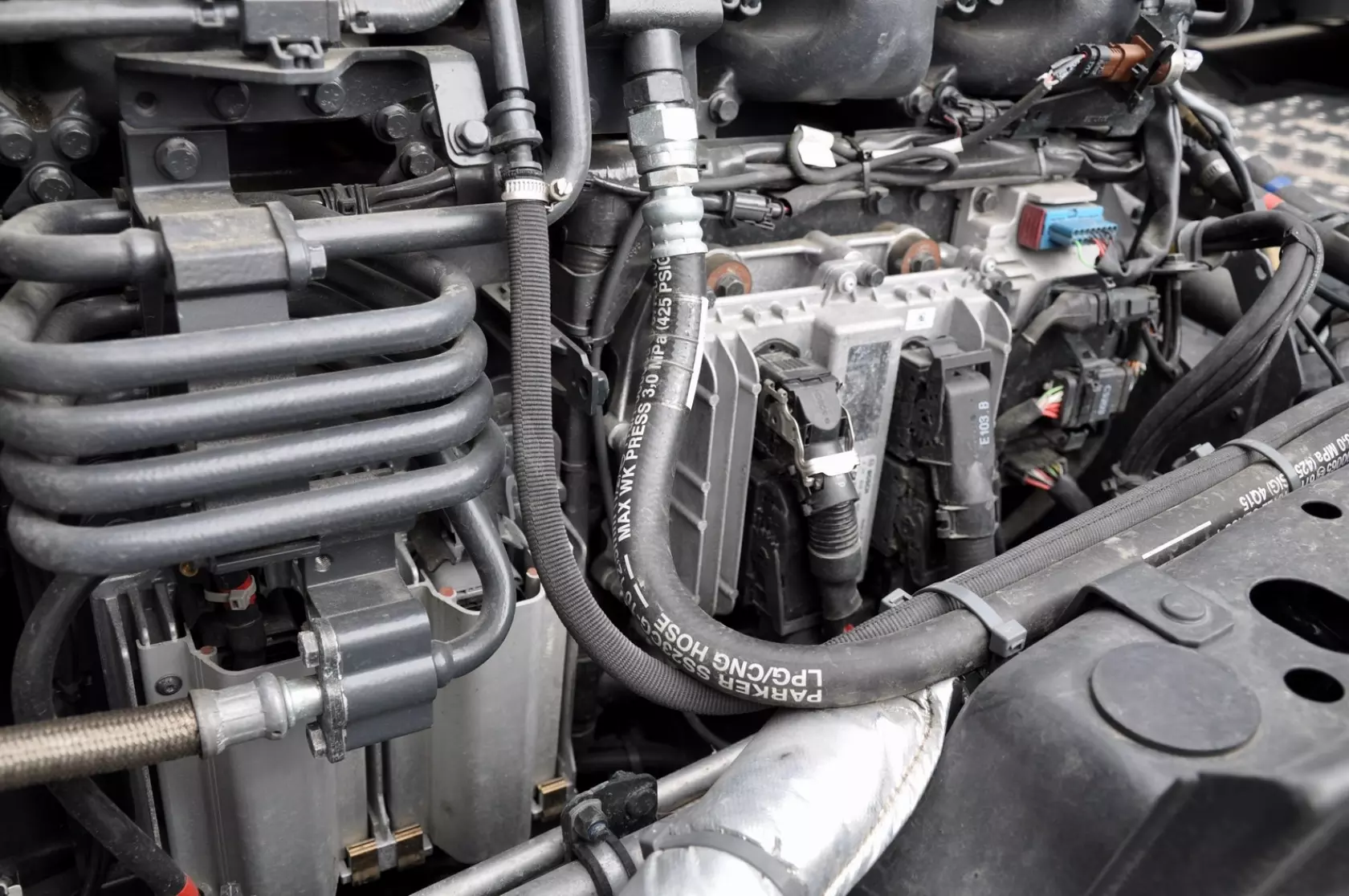

The Tescom reducer reduces fuel pressure from 16 to 7,3 bar. Once methane is filtered in the Parker Racor filter, it is fed into the engine. Notice the electrovalve, which cuts off fuel flow on the low-pressure side when the engine is switched off, but allows the engine to use up the fuel still present in the hoses  The LNG system ECU is supplied by Bosch and the low-pressure LNG hoses by Parker

The LNG system ECU is supplied by Bosch and the low-pressure LNG hoses by Parker  The refueling procedure isn't complicated, but requires basic training and certain safety measures

The refueling procedure isn't complicated, but requires basic training and certain safety measures  The only diesel-powered part of this truck is the cabin heating system, fueled from this small back-of-the-cab reservoir

The only diesel-powered part of this truck is the cabin heating system, fueled from this small back-of-the-cab reservoir  And here are the basic fittings of the LNG tank

And here are the basic fittings of the LNG tank

Scania has announced a new methane engine for 2017, but for the time being the OC09 102 is offered and has been since its debut in 2012. It's available in two power guises – 320 or 340 PS. We took the opportunity to review the more powerful variant motivating a truck tractor with a partially loaded semitrailer. The Scania G340 with a Wielton curtain trailer and 12 t of load ran a 230 km route from a Scania service centre in Rzgów to Mateuszew near Śrem, Poland. The destination was far from coincidental – we were aiming to get to PGK Śrem, a refuse collection and processing facility with a CNG/LNG refueling station on the premises.

Scania's methane-powered vehicles remain relatively niche products, with several hundred examples produced and sold annually. Most of them are CNG models, which prove more popular due to better availability of fuel retail outlets. As for manufacturing locations, Scania's Swedish and Dutch facilities assemble the methane trucks and the particular example we drove came from the Swedish plant.

The truck's engine generates its 340 PS of power at 1900 RPM, plus 1600 Nm of torque between 1100 and 1400 RPM. The engine block of the methane unit is the same as that of Scania's comparable diesels. With 130 mm of bore, 140 mm of stroke and 5 cylinders (with 4 valves per cylinder) this means a capacity of 9,3 l. The engine is turbocharged and features an intercooler. Based on a diesel as it may seem, the OC09 102 unit is a spark-ignited one, with the methane fuel system (ECU and injectors) developed and supplied by Bosch.

The engine is nearly identical with a standard diesel unit. Non-interchangeable components constitute some 18% of it, primarily engine head, fuel injectors and intake system sensors.

Mirosław Gołaszewski, sales engineer, Scania

© gazeo.comThe left tank is bigger and has a gross capacity of 409 l, compared to 319 l of the right one

© gazeo.comThe left tank is bigger and has a gross capacity of 409 l, compared to 319 l of the right oneLiquefied natural gas is stored in two cryogenic tanks, developed and supplied by Chart. They hold approx. 290 kg of LNG, providing up to 1100 km of range without refueling. There is no emergency diesel or petrol tank, so improving the existing network of LNG stations across Europe is vital for such vehicles to become more popular. Tank insulation is sufficient to sustain LNG temperature of -132° C.

The fuel is stored at a pressure of 10 bar. Should the pressure rise, methane is drawn from the tanks in gaseous form, from above the liquid gas level. Once pressure drops to sub-10 bar level, strategy changes and liquid methane is drawn from the bottom of the tank. Each tank obviously also features a refilling valve with a deaerating device, safety and maintenance valves, an LNG level indicator and an electromagnetic cut-off valve, activated when the engine is shut down.

The tank is accompanied by special fittings allowing for vapourising LNG from liquid to gas, which occurs in a heat exchanger integral to the tank and using energy from the engine's cooling system. Once LNG is vapourised, it enters the Tescom pressure reducer. It's a single-stage, piston-operated device, designed for applications on natural-gas-powered engines with capacity above 7 l. Once pressure is reduced, fuel moves on to the Parker Racor filter and further to Bosch injectors.

The engine's power output may be far from impressive, yet proved sufficient to motivate the vehicle under load. The tractor-trailer's set gross weight was 30 t, which is 10 t below the allowed limit, but then remember not all truck out there carry maximum loads at all times.

Maximum torque is available at the same RPM as in a comparable diesel. This means engine characteristics are very similar. All the ecodriving rules applicable to oil-burning units are also true when it comes to methane-powered variants.

Mirosław Gołaszewski, sales engineer, Scania

However, with 1100 km of practical range, compared to up to 5000 km for a diesel equivalent, Scania G340 LNG's range of applications is limited to national distribution. In Poland, where the test was conducted, even that would be a challenge, since there are as few as 3 LNG stations available across the country (in Olsztyn, Warsaw and Śrem). Still, LNG is an interesting alternative fuel for local applications, e.g. refuse trucks, city buses or urban distribution. LNG suppliers, such as Cryogas M&T Poland, are ready and willing to provide more fleet operators with fuel.

LNG (and methane in general) is particularly well suited for urban applications due to near-zero particulate matter emissions. As you may remember, WHO (the World Health Organisation) has labeled particulate matter as carcinogenic and outstandingly harmful to human health. Emissions aside, LNG-powered vehicles are considerably quieter than diesels. This means they can be used in densely populated areas at night or early in the morning without the risk of disturbing the peace.

Fleet operators often cite long refueling times as an argument against LNG. We checked how long the procedure takes by refilling the tanks with 209 kg of liquefied methane after 900 km from previous refueling. Watch the video to see how long it took and draw the conclusions yourself.

You may also find these interesting:

loading results...

loading results...