- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

HPDI 2.0 - new diesel-gas system by Westport

loading results...

loading results...The new power supply system is adapted to meet stringent requirements of engine and car manufacturers. It’s Westport’s response to OEMs market demand, which is starting to see the potential of natural gas as engine fuel.

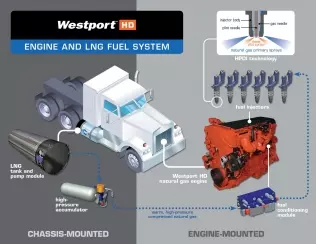

Currently, Westport is involved in the implementation of seven OEM applications of HPDI 2.0 system (High Pressure Direct Injection), ranging from the use in cars to diesel locomotives. These projects are at various stages of development.

According to the Canadian manufacturer, HPDI 2.0 is the only system of gas supply for diesel engines that is able to provide performance at the level of self-ignition engines with a significant reduction of operating costs, which arises from the possibility of replacing more than 90% of diesel oil with a much cheaper natural gas.

Good to know

Diesel engines dominate in vehicles and still enjoy great popularity thanks to their energy efficiency, durability, high torque and low maintenance costs. Unfortunately, high price of diesel oil results in constantly growing operating costs associated with fuel.

Replacing most of the fuel dose with cheaper natural gas using the HPDI 2.0 technology is carried out without reducing performance parameters of a drive unit and its energy efficiency. These engines are very similar to their versions powered only by diesel oil.

The compression ratio of an engine powered by Westport HPDI system is the same as in diesel drive unit, so there is no need for changes in the main components of the engine. All the advantages resulting from high compression (mainly the engine’s high efficiency) are in place.

The HPDI technology is based on the thermodynamic cycle used in self ignition engines, which is more efficient than the Otto cycle used in spark ignition engines (SI). SI engines include petrol engines and those powered by gas fuels.

Diesel engines with Westport HPDI power system do not have a choke valve to control the excess air ratio as in the classic (Otto cycle) gas engines. Gas injected directly to combustion chambers at the end of the compression stroke can be burnt over a wide range of excess air factors.

Engine powered by the HPDI system remains a self-ignition drive unit without the risk of knocking. Natural gas is its primary fuel and a small amount of diesel oil is used to self-ignite the whole dose. Both types of fuel (natural gas and diesel oil) are not pre-mixed with intake air. This happens in combustion chambers. As a result, there is no risk of knocking. There is therefore no need to lower the compression ratio, so power and torque remain at the same level as when the engine is powered by diesel oil. Compared to diesel fuel, directly injected natural gas burns at lower temperature. Therefore, an engine powered by the HPDI system has a little tendency of having particulates and oxides of nitrogen formed in it.

The HPDI 2.0 system can be adjusted to a specific group of vehicles, both in terms of performance, driving characteristics and nature of work, as well as a completely different use of the drive unit (in a locomotive or watercraft).

Westport HPDI 2.0 is a complete solution that offers high flexibility when installing the system during the first assembly at a car or engine manufacturer. The development of Westport HPDI 2.0 system resulted in patenting of many technologies. Since 2007, Westport has filed 42 patent applications for inventions related to the HPDI system.

characteristics of the HPDI 2.0 on page 2!

Left: 50%

You may also find these interesting:

loading results...

loading results...