- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Bosch Dual-Fuel - future of diesel engines?

loading results...

loading results... © Fleet and FuelsBosch DG Flex – first generation of a system dedicated to diesel engines with mechanical diesel oil injection

© Fleet and FuelsBosch DG Flex – first generation of a system dedicated to diesel engines with mechanical diesel oil injectionIt seems likely, at least for some time. This applies particularly to certain specific uses of self-ignition engines.

Powering marine diesel engines with two types of fuel simultaneously is becoming increasingly popular, particularly due to the tightening of emission standards. Also North American railways are testing such engines, looking for some savings (American railways are second biggest consumer of diesel oil, after US Navy) and a way of reducing emissions of harmful components. Specialists claim that this might be the era of LNG in railway industry, as it may be used in traction engines.

This type of engines is also becoming widely used in road transport due to possible savings and increasingly stringent emission standards. Powering engines with diesel oil and natural gas in America became popular due to American gas revolution – mass production of cheap natural gas from shale deposits.

Therefore, many companies are developing gas systems for diesel engines, which allow the conversion of already operating engines to dual fuel power supply. Many manufacturers are also working on engines simultaneously powered by diesel oil and natural gas. Bosch is one of the companies that works on such a system, and this might mean that this solution is considered as one of the possible ways of developing diesel engines.

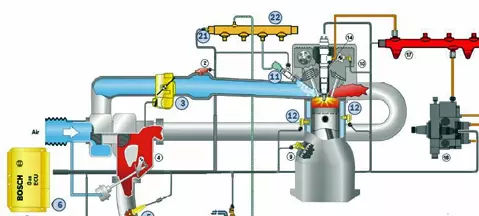

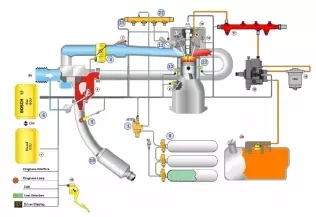

© BoschDiagram of Bosch Dual Fuel system: 1 – gas pressure regulator, 2 – air pressure and temperature sensor, 3 – throttle, 4 – turbocharger’s release valve, 5 – oxygen sensor, 6 – CNG controller, 7 – diesel oil controller, 8 – CNG tanks, 9 – engine speed sensor, 10 – gas pedal, 11 – CNG injector, 12 – knock sensor, 13 – engine temperature sensor, 14 – diesel oil injector, 15 – engine phase sensor, 16 – high-pressure pump, 17 – diesel common rail, 18 – fuel filter, 19 – oxidation catalyst, 20 – diesel oil tank, 21 – gas pressure and temperature sensor, 22 – CNG fuel rail

© BoschDiagram of Bosch Dual Fuel system: 1 – gas pressure regulator, 2 – air pressure and temperature sensor, 3 – throttle, 4 – turbocharger’s release valve, 5 – oxygen sensor, 6 – CNG controller, 7 – diesel oil controller, 8 – CNG tanks, 9 – engine speed sensor, 10 – gas pedal, 11 – CNG injector, 12 – knock sensor, 13 – engine temperature sensor, 14 – diesel oil injector, 15 – engine phase sensor, 16 – high-pressure pump, 17 – diesel common rail, 18 – fuel filter, 19 – oxidation catalyst, 20 – diesel oil tank, 21 – gas pressure and temperature sensor, 22 – CNG fuel railBosch carries out development and testing of cars in South America, specifically in Brazil. The conceptual work on the first gas-diesel system dedicated to self-ignition engines with mechanical diesel oil injection was started by Bosch in 2006. Two years later, approval tests were completed for the first self-ignition engine powered simultaneously by diesel oil and natural gas. The same year, research was started on powering diesel engines with electronic control of fuel injection with natural gas, and in 2009 the company started developing dual fuel applications for engines in new cars.

The use of Bosch Dual-Fuel power supply does not change the basic configuration of a diesel engine – combustion process is still initiated by self-ignition of a small dose of diesel oil. The engine is equipped with an additional injection system (for fuel gas) and a throttle in the intake system, which controls the amount of air flowing into the engine.

Diesel engine – adapted to simultaneous diesel oil and natural gas supply – may operate like a conventional self-ignition drive unit or in a dual fuel mode, where diesel oil is mostly substituted by gas. Power system components and Bosch Dual-Fuel software allow the use of natural gas in various forms (CNG, LNG or biomethane).

Knock sensors are used in the gas dosing system. They provide diagnostic and monitoring of the system in simultaneous diesel oil/natural gas supply in a closed loop. Thanks to such algorithm of the engine’s work, the rate of replacing diesel oil by natural gas is high.

Maximizing the amount of diesel oil that gets replaced by cheaper natural gas or biomethane means that operating costs can be significantly reduced.

The prototype of an engine that meets Euro IV standards, is equipped with EGR system (exhaust gas recirculation), and Bosch Dual-Fuel system, and it was tested on a test bench in order to obtain the highest dose of gas compared to diesel oil. It was possible to substitute more than 85% of oil with gas. To achieve this result, Bosch Dual-Fuel monitors many engine control parameters, i.e. diesel oil injection timing, the dose of diesel oil, diesel oil injection pressure, natural gas injection timing, and the dose of that type of fuel.

These parameters are chosen so that an engine can operate without knocking – this is supervised by the abovementioned knock sensor which is a part of a gas supply system.

Studies have shown that the simultaneous use of diesel oil and natural gas reduces the content of particulate matter in exhaust gas to such a level that using particulate matter filters (DPF) is not required. Compliance with Euro 6 standard is possible in dual fuel engines only when using selective catalytic reduction (SCR) system that reduces the amount of nitrogen compounds without using exhaust gas recirculation.

In order to have low emissions of carbon monoxide and hydrocarbons, dual fuel engine requires the use of platinum-based oxidation catalyst, as platinum is necessary to convert methane (CH4).

As you can see, Bosch Dual Fuel system enables reaching emission levels that meet the newest standards without the use of complicated methods of exhaust gas after-treatment. With the addition of gaseous fuel, the previously very complex self-ignition engine is simplified significantly. That’s an extremely big advantage of this solution and it’s what should make it so profitable.

You may also find these interesting:

loading results...

loading results...