- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

loading results...

loading results... © V-tech

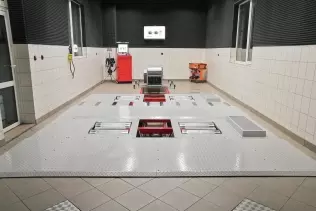

© V-tech A chassis dynamometer also becomes a popular tool for conversion workshops. Properly configured, stripped of some advanced features, a chassis dyno is cheaper and much more available to the average workshop.

Autogas system calibration

Modern (4th generation a.k.a. sequential injection) autogas systems require certain amount of fine tuning to work properly. This is often done during a test drive in a regular traffic. Forcing extreme engine operating conditions (e.g. extreme load) on the road is either impossible or very dangerous, especially that at the same time the installer needs to observe readings of diagnostic and calibration devices. Certain useful tools cannot even be used during a test drive, because they simply would not fit into a car.

This is when a dyno proves a priceless substitute. In the opinion of those who switched from real-life test drives to dyno tests, the number of customers reporting faulty functioning of their autogas systems as a result of imprecise calibration virtually drops to zero.

A dynamometer in a nutshell

A chassis dynamometer is a device commonly associated with power and torque measurement. The measurement is done indirectly by recording the torque on chassis dynamometer rollers. Knowing this value and the rollers' rev speed enables measuring the vehicle's power.

This is not all – a dynamometer also allows simulating real-life load conditions, which in turn makes it possible to measure fuel consumption and emissions or examine the performance of various vehicle systems. Measuring engine flexibility across different speed ranges is also an option, as well as determining speedometer or tachograph precision and examining a vehicle's climbing ability.

Dyno classification

There are two basic types of chassis dynamometers: inertia (where load is the rollers' mass, drivetrain resistance and rolling resistance) and brake (the engine can be subject to any load thanks to brakes used). Brake dynos allow testing drivetrain efficiency under various conditions, which makes them more suitable for autogas system installers.

© V-techV-tech dynamometers function all over the world. Here you see a 4x4 dyno in Bend (USA), mobile version standing on the floor

© V-techV-tech dynamometers function all over the world. Here you see a 4x4 dyno in Bend (USA), mobile version standing on the floorThe possibility of simulating a variety of loads and maintaining them over a long period of time allows installers to observe and adjust autogas system presets. This is crucial for LPG conversion specialists as it enables them to calibrate the system very precisely and detect any potential glitches, which may only be revealed under certain conditions, e.g. at ultra-high speeds.

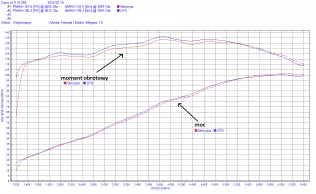

© V-techThanks to the possibilities a dynamometer offers, an engine converted to run on LPG has the same performance as on petrol, sometimes actually better

© V-techThanks to the possibilities a dynamometer offers, an engine converted to run on LPG has the same performance as on petrol, sometimes actually betterV-tech dynamometers

V-tech Dynamometers offers a wide range of equipment allowing test the car drive train system on one or both axles. Both inertial and brake dynamometers are available. Each brake model can operate in inertia mode and each inertia dyno can be upgraded to become a brake one. Modular construction is an important and useful feature of V-tech's products.

© V-techAll V-tech dyno rolls are knurled, which enhances grip. Chrome protects surfaces from rust for years on end

© V-techAll V-tech dyno rolls are knurled, which enhances grip. Chrome protects surfaces from rust for years on endMeasuring range for V-tech dynos ends at 2000 PS. Special dynamometers for two-wheelers and quads are also offered. Two-axle dynos are additionally equipped with mechanical front and rear axle synchronization system, allowing for measurements of vehicles equipped with active center differential systems and advanced traction control systems.

The devices can be used as mobile ones (as long as entry rails are provided, because a mobile dyno stands on the ground, above its level) or built into the floor.

The VT-2/B1 model is particularly recommended to autogas installers. It is a single-axle dyno equipped with a Telma eddy-current brake, with an 800 Nm braking torque. This is sufficient for calibrating cars with engines of up to 600 PS power.

First-hand experience

The advantages of V-tech dynamometers have been recognised both by major companies, who use them for research and development projects, and autogas system installer workshops, proving to be excellent calibration and fine-tuning tools, while also broadening the scope of services that can be offered to customers (chiptuning, power and torque measurement).

We have asked the dynos' end users from both kinds of companies to share their opinions.

We have been using a V-tech dyno for around two years now. It gives us the opportunity to simulate various conditions and loads – including extreme ones – in one place, which in turn allows to prepare a precise program for each autogas ECU. I suppose this could be called autogas chiptuning, with LPG portion adjusted perfectly to the needs of a calibrated engine. Additionally, a printout of power and torque curves serves as evidence of a well-done job – both for us and our customers. Parameters are nearly identical for petrol and LPG, sometimes actually even higher for autogas.

Piotr Oleksyk, Czakram

BRC's exclusive distributor in Poland

We have been using a V-tech dyno since 2002, which makes us one of the first companies in the sector who did. This significantly raised the quality of our services and expanded the number of satisfied customers.We have converted cars which had been driven for hundreds of kilometres just to be converted at our workshop exactly because we have a dyno. With the ability to simulate any conditions in the workshop, we are able to solve „tough cases” much quicker and improve faulty conversions.

Przemyslaw Cebula, EKO-CAR.com

LPG sector company with 20 years' experience

Zobacz stronę producenta:

BRCYou may also find these interesting:

loading results...

loading results...