- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

EVAS - power of experience

loading results...

loading results... © EVAS

© EVAS  This is where in the world EVAS products can be found

This is where in the world EVAS products can be found  EVAS has received a number of certificates to confirm the quality of its products worldwide

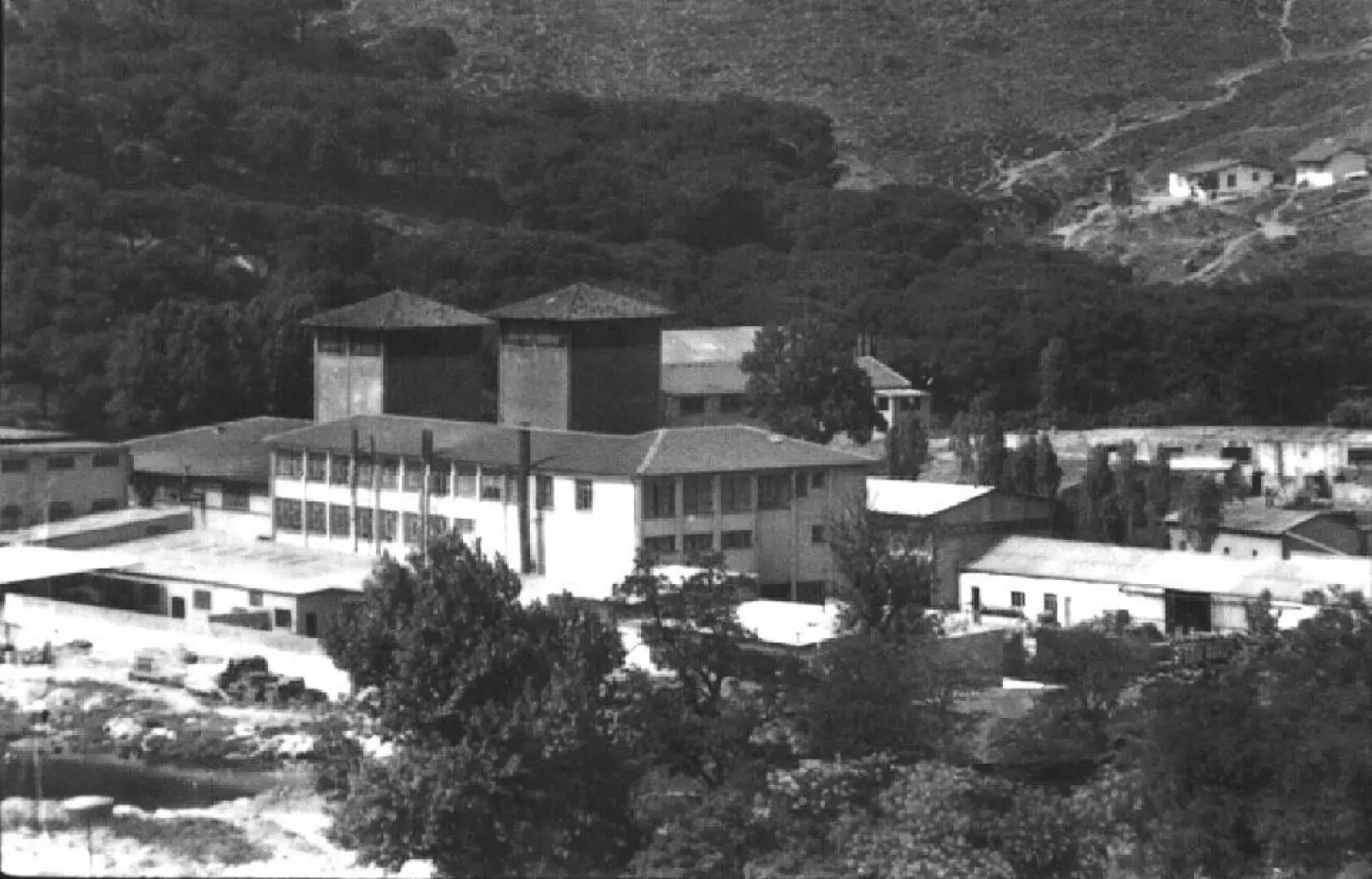

EVAS has received a number of certificates to confirm the quality of its products worldwide  This is where the EVAS story began back in 1963

This is where the EVAS story began back in 1963

© EVASThe company's HQ remains in the same location since 1988, however well modernised and more efficient

© EVASThe company's HQ remains in the same location since 1988, however well modernised and more efficientEVAS, Turkey’s leader among LPG cylinder and autogas tank manufacturers, was founded in 1963 with an annual capacity of fewer than 10 thousand LPG cylinders. Today, with its modern production, testing and inspection facilities, annual production has reached over two million pressure vessels. EVAS is proud to have manufactured more than 50 million vessels since its inception. EVAS, a part of the SHV ENERGY group, has been producing high quality vessels at competitive prices for its Asian, European, African, South American and Australian customers. With its five decades of experience, EVAS produces pressure vessels for industrial, domestic and automotive usage in capacities ranging from 4,95 to 120 l, in accordance with ECE-R and ADR regulations and as per other country/regional or customer standards and specifications.

Good to know

The company was established back in 1963, becoming the first in the country to produce pressure containers for LPG storage. Between 1989-91 Evas was privatized and became a part of the French conglomerate Primagaz, which in turn was taken over by the SHV Holding. As a result, Evas has been within the structure of the latter corporation since 1999, all the while working to expand technologically and commercially. Speaking of expansion, EVAS is now activating their new facility located in Rio de Janeiro (Brazil). This exciting advancement is a considerable step towards providing quality products in this part of the world where the brand name itself has become a synonym of quality. Make sure you include the EVAS factory to your trip right before you watch the 2014 football World Cup finals.

EVAS staff of all levels (management, engineers, sales executives and workers) has a strong feeling of mission and responsibility in delivering the best product and in maintaining and further strengthening the company's leading market standing. Proper care is also taken of making the tank production process as sustainable and environmentally neutral as possible, as well as constant improvement of manufacturing technology and staff qualifications.

As for production technology itself, EVAS uses new generation welding machines knowing that welding is the most important process for pressure vessel manufacturing. Even though the company uses good quality material from reliable suppliers, steel is approved before tank manufacturing. It is examined in accordance with the requirements of the EN 10120 norm in order to confirm producer certificates before any tanks are actually made. And once they are, welding quality is first assessed visually and then tested with the use of X-ray. Needless to say, filming and evaluation of the welding points with X-ray is done by experienced personnel who are trained accordingly. Furthermore, each and every tank is pressure tested at 30 bars and 2 out of every batch of 200 are randomly subject to further testing procedures, including stretching, squeezing and burst trials. Finally, structural micro-

© EVASThanks to flexibility and improved finishing process, EVAS is able to customise their products in order to make them even more appealing

© EVASThanks to flexibility and improved finishing process, EVAS is able to customise their products in order to make them even more appealingand macroanalyses are performed. With the confidence of high-tech laboratory devices and well trained personnel, the company is capable of doing all relevant tests themselves. Tanks are powder-coated with anticorrosion paint and packed in a way protecting them from mechanical damage during transport and storage.

Appropriately for a company offering its products in a number of markets across the globe, EVAS is rapidly enlarging its range of tank types and sizes, not to mention various cosmetic applications on the products. The most general division is obviously into cylinders and toruses, which in turn are available in various diameter and height/length combinations to make sure all customers, regardless of required applications, can find the right container, best tailored to their needs. The range will eventually expand ever further as EVAS intends to enter more markets in the near and more distant future. So if you haven't heard of the company yet, you're bound to hear about it sooner or later.

You may also find these interesting:

loading results...

loading results...