- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Skoda Citigo TwinPower - the blessed one

- Home page

- Up to date

- Reportages, interviews, road tests

- Road tests

- Skoda Citigo TwinPower - the blessed one

« Powrót

loading results...

loading results... © gazeo.pl

© gazeo.pl  The Evo-A injectors are quite noisy, but - more importantly - very efficient

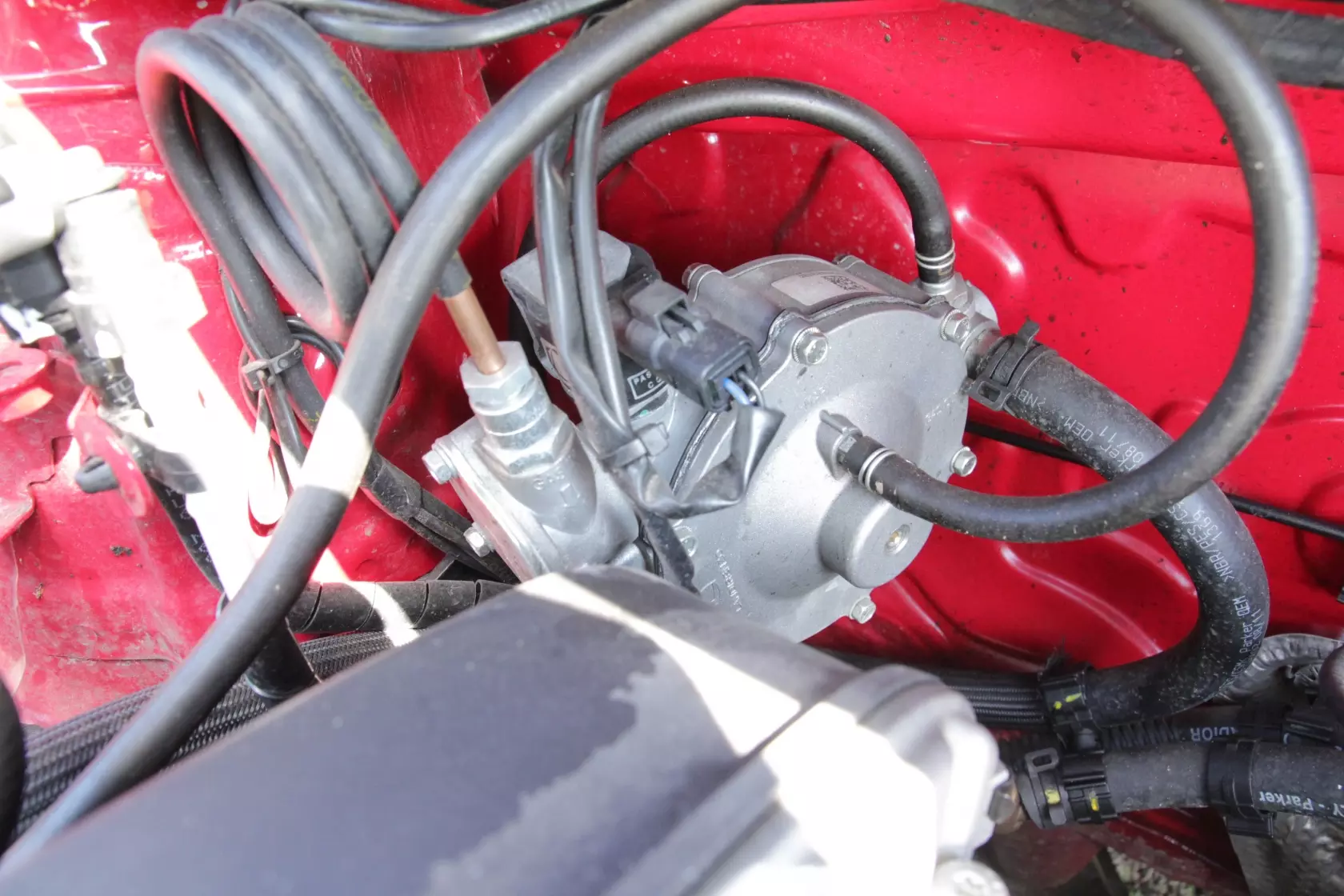

The Evo-A injectors are quite noisy, but - more importantly - very efficient  The LI-10 reducer offers more potential than required, but too much is still better than too little

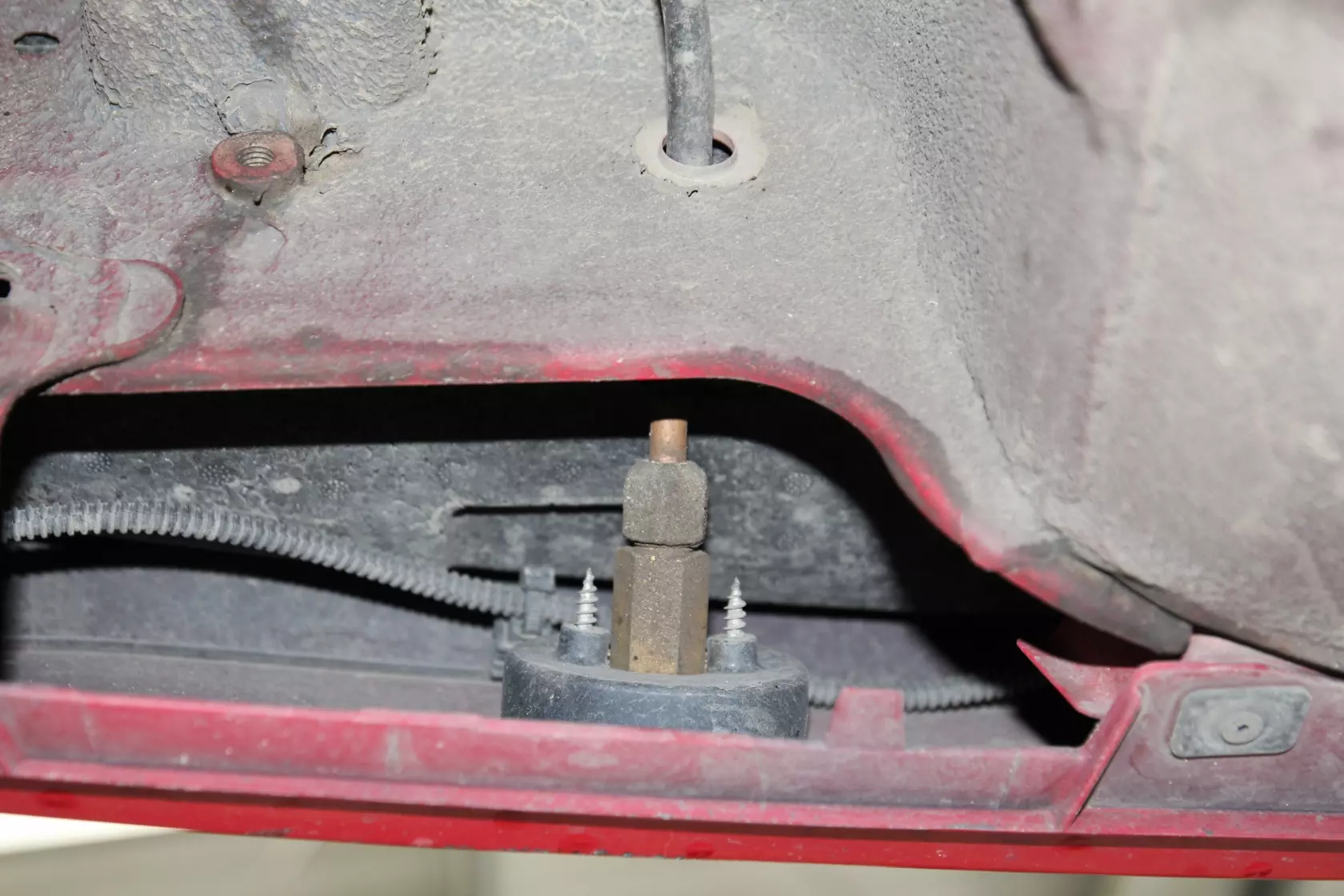

The LI-10 reducer offers more potential than required, but too much is still better than too little  A portion of bootcapacity is taken up by the tyre saver kit, but it is easily removable. The shelf does not lift automatically with the rear hatch and needs manual operation

A portion of bootcapacity is taken up by the tyre saver kit, but it is easily removable. The shelf does not lift automatically with the rear hatch and needs manual operation  Quality and reliability to the smallest detail - even the pressure/temperature sensor has its own fitting bracket

Quality and reliability to the smallest detail - even the pressure/temperature sensor has its own fitting bracket  The placing of the filler valve is far from coincidental - it helps avoid puncturing anything apart from the plastic fender

The placing of the filler valve is far from coincidental - it helps avoid puncturing anything apart from the plastic fender  Fitting the tank caused an indentaion in the wheel well bottom, so now Skoda uses special inserts to prevent this

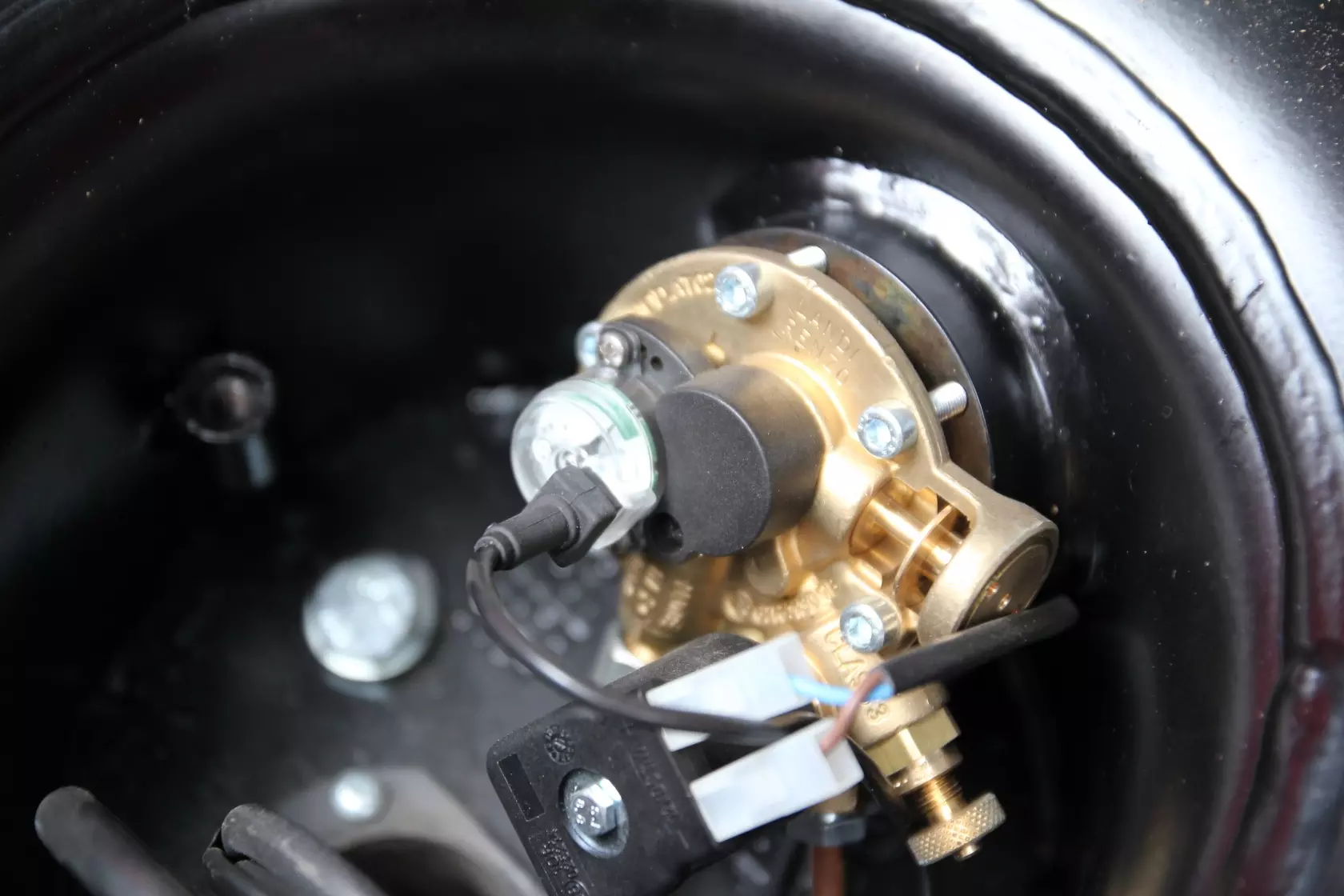

Fitting the tank caused an indentaion in the wheel well bottom, so now Skoda uses special inserts to prevent this  Virtually all the LPG components beside the tank bear the Landi Renzo nameplate, multivalve included

Virtually all the LPG components beside the tank bear the Landi Renzo nameplate, multivalve included  LPG feed lines are far from the exhaust system, which incidentally "helps" by not running right across the middle of the underbody

LPG feed lines are far from the exhaust system, which incidentally "helps" by not running right across the middle of the underbody  The petrol-to-LPG switch is easy to access and operate, but not always clear to read from

The petrol-to-LPG switch is easy to access and operate, but not always clear to read from  The optional detachable GPS system brings a little life to the otherwise dull interior

The optional detachable GPS system brings a little life to the otherwise dull interior

© gazeo.comThe basic difference between this Citigo and the previous one we drove is... the colour! Finding more requires a closer scrutiny

© gazeo.comThe basic difference between this Citigo and the previous one we drove is... the colour! Finding more requires a closer scrutinyQuite frankly, differences are few. Even the ECU – the Omegas Evo, a simpler and more affordable version of the more sophisticated and expensive systems by Landi Renzo, like the classic Omegas – is based upon the same AEB electronics as the controller in the Stella Polare system used on our previous Citigo test car. Also the injectors (AEB I-plus model, three nozzles on a common rail, here under the name EVO-A) are identical. As usual, the devil is in the detail. The detail in this case means different reducers and tanks – while Elpigaz uses components from its own catalog, Landi Renzo employs their own vaporiser, but buys tanks from outside suppliers. Autogas systems on both Citigos we have driven further vary in terms of settings, but we will come to that in due time.

Meanwhile, let us focus on the reducer. The state of matter of LPG coming from the tank is changed from liquid to gaseous in an LI-10 vaporiser, which is located on the left and deep in the back of the engine bay. The device is fairly new in Landi Renzo's range and available in two variants, varying in maximum power of engine to be converted. One of them is Standard (up to 140 kW/190 PS), the other one – Turbo (160 kW/218 PS). Using either of them on a Citigo is a little bit of art for art's sake, since the three-cylinder, one-litre MPI engine has only 44 kW/60 PS of power, which means an LI-02 reducer (also used as part of Omegas Evo kits) would be fully sufficient, as it has enough efficiency to „feed” engines with up to 90 kW/122 PS.

© gazeo.comSkoda decided to place LPG filler valves in the fender. It is only moderately convenient, but at least does not require puncturing any metal elements

© gazeo.comSkoda decided to place LPG filler valves in the fender. It is only moderately convenient, but at least does not require puncturing any metal elementsAnother hardware difference is, as we have said already, the tank. The spare wheel well houses a 600 mm diameter and 200 mm height toroidal tank by STAKO. Its 42-litre gross capacity means in parctice it can hold 33,6 l of autogas. Truth be told, the tank is not light as it tips the scales at 22 kg when empty and without the multivalve, but in return it gives the mini (manufactured in Slovakia along its twin siblings – Volkswagen Up! and Seat Mii) a respectable range. As for the tank itself, Skoda has already introduced some modifications in the conversion process since fastening the tank to the bottom of the wheel well caused indentation of that bottom. To avoid this, specially designed liners are now inserted between tanks and well bottoms to stiffen the otherwise empty space, so that the car body is not deformed.

© gazeo.comAlthough it is not Citigo's natural habitat, the car is suitable for highway driving, too

© gazeo.comAlthough it is not Citigo's natural habitat, the car is suitable for highway driving, tooThe autogas filling valve has been placed at the rear, low and to the right of the fender. This might not be particularly convenient, but makes use of the car's original body perforation and does not require further puncturing it. The entire conversion process has been performed with aesthetics and durability in mind, too – the components located beneath the bonnet have been precisely and rigidly fixed to the body by means of dedicated supports and brackets, while all wiring harnesses have been properly isolated. Order and sturdiness are also the appropriate words to define what is beneath the car as copper gas lines have been carefully laid and fixed to the floorpan. In future, copper pipes are going to be replaced with flexible plastic ones. Inside the cabin, only the petrol-to-gas switch, located on the dashborad, left of the steering column, shows that this is an LPG-powered car. It is easy to follow the fuel level indicator, unless it is very sunny – diodes become illegible under strong light. From the point of view of ergonomy, placing the switch somewhere on the center console or around the shift lever would be a much better solution, at least in our humble opinion. Also, it is a pity Skoda did not replace the standard Landi Renzo switch with a dedicated one that would match the interior. The way it is, the switch clearly stands out as delivered by an outside supplier, even though the autogas system is dedicated for this particular model. Of course, Citigos are converted individually by Skoda's service stations, not on the assembly line in a factory, but still replacing the switch seems like a good idea and an easy thing to do, too. Especially for a company as experienced as Landi Renzo.

You may also find these interesting:

loading results...

loading results...