- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Oil additives - what do you know about them?

loading results...

loading results...9. Fragrances – used to eliminate odors of some oil ingredients.

These additives are used in increased amounts in oils dedicated to LPG-powered engines.

In engines fueled by autogas, higher gas combustion temperature accelerates base oil oxidation and degradation of physicochemical properties (e.g. washing and dispersing).

Due to this, the amount of detergents, antioxidants and corrosion inhibitors is higher than in traditional oil.

10. Antioxidants

Operating temperature of an LPG-powered engine higher than that of petrol-powered one causes higher oil wear (despite the fact that it still looks fresh) and the loss of basic physicochemical qualities of oil. Antioxidants prevent this.

Antioxidants (oxidation inhibitors) – additives particularly important in modern LongLife oils or oils that are used in turbocharged or autogas-powered engines. These additives prevent oxidation of oil and significantly slow down the process of “ageing” of the base oil. They react with oxygen faster than oil, thereby delaying the ageing process of oil. Oxidation is quickest during operation at high temperature, so these additives are very important in engines that are more thermally loaded.

Excess – no side effects.

Deficiency – causes premature oil wear and changes oil viscosity and physicochemical properties.

11. Corrosion inhibitors

As a result of LPG combustion, acidic compounds are produced that leak into the crankcase despite the use of O-rings in internal combustion engines. These compounds are characterized by high corrosion aggressiveness, especially on the bearings. Inhibitors effectively slow down this process.

Corrosion inhibitors – they prevent two types of corrosion. One is corrosion of ferrous metals that involves oxidation of metals. This occurs quicker in the presence of water vapor. The second type of corrosion is chemical corrosion of various metals, including non-ferrous metals (brass, aluminum).

Excess – no side effects.

Deficiency – causes engine corrosion. This may be corrosion caused by oxygen and water vapor, as well as chemical corrosion.

12. Detergents

Higher combustion temperature of LPG-powered engines results in more intensive deposition of sludge material. One way around this is to increase the amount of detergents.

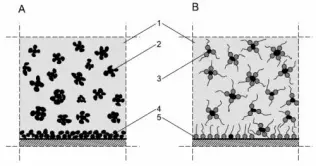

© TotalHow detergents work: A – base oil without detergent, B – base oil with detergent; 1 – base oil, 2 – solids particles agglomerates, 3 – molecular impurities surrounded by adsorbed detergent molecules, 4 – deposit adhered to a metal substrate, 5 – detergent molecules adhered to the metal substrate remove deposits

© TotalHow detergents work: A – base oil without detergent, B – base oil with detergent; 1 – base oil, 2 – solids particles agglomerates, 3 – molecular impurities surrounded by adsorbed detergent molecules, 4 – deposit adhered to a metal substrate, 5 – detergent molecules adhered to the metal substrate remove depositsDetergents – additives that keep the engine clean. Their task begins the moment contaminants are produced (e.g. carbon deposits or sludge). These additives dissolve those compounds and keep them in oil in order to get rid of them from the engine during oil replacement.

Excess – causes oil foaming. Intensive washing out of impurities occurs and leads to chemical corrosion.

Deficiency – causes increase in engine contamination, deterioration of lubrication, as well as increased operating friction and temperature. It usually leads to engine seizure due to lack of lubricant.

Sometimes you’ll come across a definition that calls some of additives “stabilizers”. This group includes anti-wear additives and viscosity modifiers.

If they are to perform their tasks effectively, additives in engine oils can’t be filtered out, that’s why the size of their particles is adjusted to oil filters. Additives offered in retail network for self-dispensing (known as Moto Doctor) are an exception. They are based on particles of ceramic, molybdenum and copper which may accumulate in filters and oil ways. As a result, their excess may clog the oil filter and lead to a situation when oil circulates in the lubrication system bypassing the filter and carrying metal particles or other contaminants harmful to the engine. Accumulation of the aforementioned particles in oil ways can to some extent reduce or even completely stop oil from reaching the so-called lubrication nods – components that are extremely important for proper functioning of the engine. As a result, oil may not be able to reach the camshaft.

One wonders whether modern engines would be able to work on oil based solely on base oils. It would be impossible as modern engines that operate in more and more extreme conditions with increasingly longer mileages between service have much higher demands than can be met by oils manufactured a dozen years or even decades ago. This is due to technological progress in the field of engines and fuel. Another crucial factor are the increasingly stringent emission standards, which are a strong incentive for the development of engines and engine oils.

loading results...

loading results...