- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Diesel-gas in Switzerland - in progress

loading results...

loading results...These results were achieved thanks to simultaneous diesel and natural gas supply (diesel-gas system). Interest in this type of fuel is not accidental, since the extraction of natural gas from shale deposits in the United States – which made the country’s economy independent from importing this fuel – may affect (after running export) prices of methane around the world.

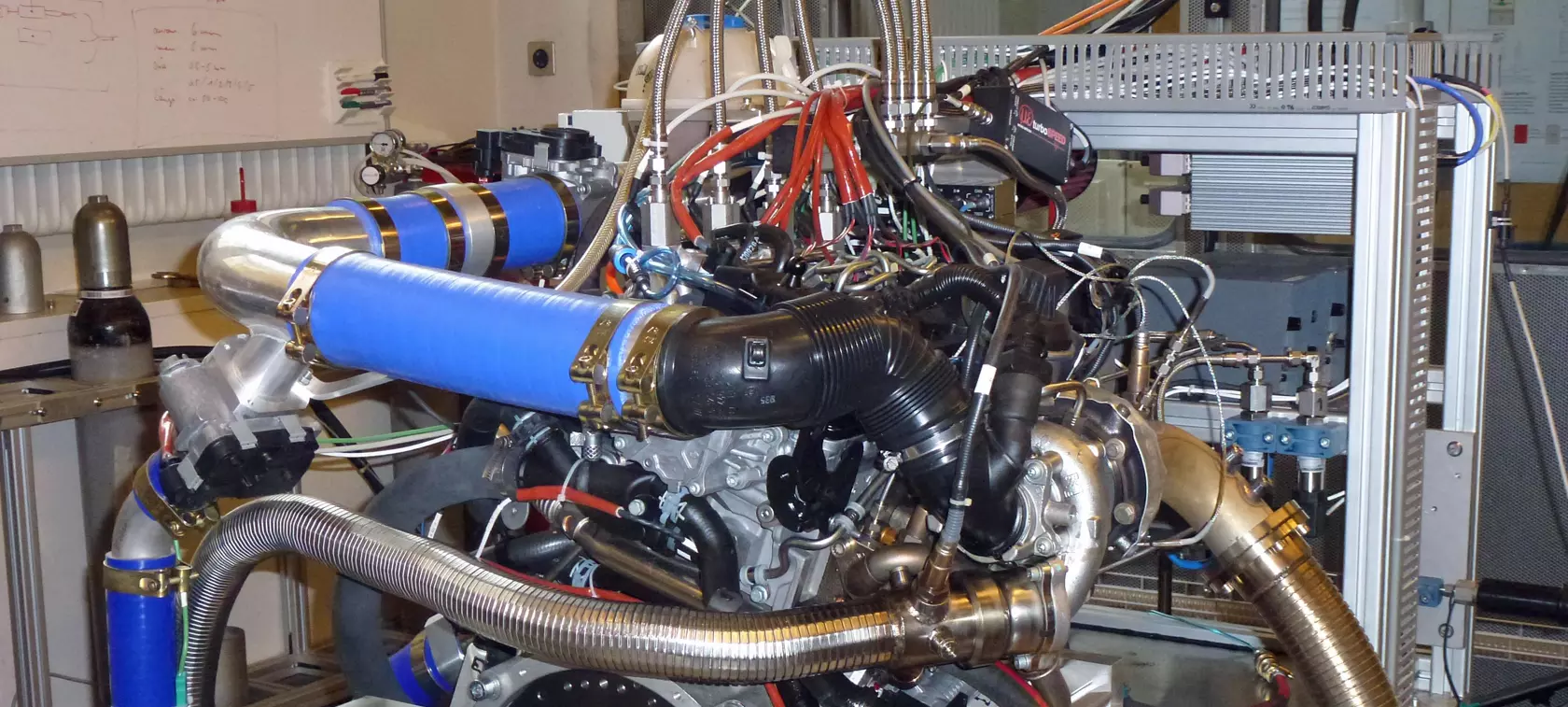

Scientists from the Institute for Dynamic Systems and Control have developed a self-ignition power unit powered by natural gas (supplied to the intake system) which constitutes even up to 98% of the total amount of fuel. The rest is diesel, which – injected at the end of the compression stroke – ignites spontaneously, initiating the process of burning both types of fuel.

Swiss scientists redesigned a conventional diesel engine from Volkswagen Golf (2.0 TDI). The engine with a compression ratio of 16.5 reached a level of efficiency of 39.6%.

According to the Swiss scientists, this way of powering an engine (diesel-gas) – where both diesel and gaseous fuel are supplied simultaneously to combustion chambers – is mainly used in stationary engines that work under constant load and at constant speed. Using such solutions in a traction engine (used in a vehicle), where its load and engine speed are constantly changing, is much more complicated.

Tobias Ott and Christopher Onder from prof. Lino Guzzella’s team have developed a system for electronic control over combustion for this type of engine. 4 pressure sensors form the heart of this system. They measure its value in engine cylinders. Data achieved through this – processed using complex algorithms – ensures precise injection timing and its duration, so that the engine works with the greatest possible efficiency.

The scientists also studied a hybrid, parallel driving system, which will further reduce energy consumption and exhaust gas emissions. But the engine can be successfully used in a car on its own.

Studying the engine on a specially designed bench, the researchers showed a reduction in emission levels in the drive unit powered this way, though there are still some technical problems that need to be solved.

At the moment, we are concentrating particularly on the temperature in the catalytic converter. It has to reach at least 300 degrees. Our combustion engine converts heat energy into mechanical energy with such efficiency that the exhaust gas is not warm enough to create sufficient heat, particularly after start-up.

Tobias Ott – a doctoral student in prof. Lino Guzzella’s research group

Another member of this team, Christopher Onder, is convinced that an engine powered simultaneously by diesel oil and natural gas may be mass-manufactured as early as in five years. The condition is to find a suitable industrial partner who will undertake manufacturing a prototype of such engine.

The scientists are aware that the success of this solution depends on the cost of its production. In the case of a gas-diesel system based on existing technology, which can be implemented quickly, the cost is relatively low, and this type of engine may be a technological bridge for 10 to 20 years before more efficient solutions are developed. Negotiations with car manufacturers are already underway and – as shown by the example of Clean Air Power and Westport – such solutions can be successfully commercialized.

This project is supported by the Competence Center Energy and Mobility and the Swiss Federal Office of Energy.

You may also find these interesting:

loading results...

loading results...