- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Cut autogas consumption with ignition variator

loading results...

loading results... © Bosch

© Bosch Good to know

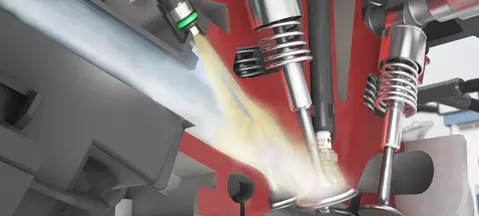

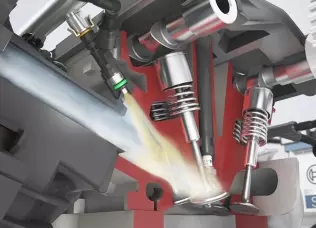

An ignition advance angle variator is connected into the crankshaft position sensor's circuit and additionally (as an option) into the circuit of the camshaft(s) position sensor(s). The device generates a signal for the petrol ECU advanced by a few to a dozen or so degrees compared to the sensor's (or sensors') signal, which results in rising the ignition advance angle.

The thing is almost all engines (well, apart from diesels, of course) are built with petrol in mind and optimised for that particular fuel, while autogas in nearly always complementary, an alternative option. This means compromises are necessary when it comes to LPG or CNG. What it further means is that the potential of gaseous fuels cannot be fully untapped, which is especially true of engines converted to run on natural gas.

To squeeze more of what there is to squeeze out of gaseous fuels, engines powered with them more and more often feature ignition advance angle variators. These devices modify the ignition advance angle when an engine runs in LPG or CNG mode to compensate for the prolonged combustion process of these fuels as compared to petrol.

© BoschGaseous fuels have different properties than petrol, so they should be treated differently to expose their full potential

© BoschGaseous fuels have different properties than petrol, so they should be treated differently to expose their full potentialYou see, the ignition advance angle in any petrol engine is set with petrol in mind, so maximum combustion pressure occurs directly after the piston reaches top dead centre, because this allows to best utilise the energy stored in the fuel and the engine generates as much power and torque as it can.

Now, if you replace petrol with a gaseous fuel, which by default combusts slower, the maximum combustion pressure (with the ignition advance angle set identically as for petrol) will occur way after the top dead centre (TDC). So in order for the maximum combustion pressure on LPG or CNG to occur right after TDC as well, the ignition angle must be modified so that ignition takes place sooner. And that's exactly what a variator does.

Using ignition advance angle variators hasn't been very common to date. Considering the possibilities of these devices and the benefits they bring, they should in all probability become more popular soon, since they make it possible to boost performance (power and torque) and flexibility of the engine, all the while cutting fuel consumption and emissions. According to variator manufacturers, fuel economy could improve by as much as 10% when you use one. And that's because engine efficiency is improved by means of optimising the ignition advance angle with gaseous fuels in mind.

Extra flexibility as a result of improved power and torque after implementing an ignition advance angle variator is particularly true for turbocharged engines, although naturally aspirated units also offer room for significant improvement.

loading results...

loading results...