- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Kia Cee’d LPdi - directly and fluently

- Home page

- Up to date

- Reportages, interviews, road tests

- Road tests

- Kia Cee’d LPdi - directly and fluently

« Powrót

loading results...

loading results... © gazeo.com

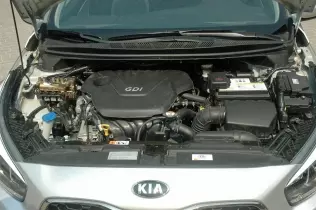

© gazeo.com  Even after removing the plastic cover from the engine, it’s hard to figure out immediately that you see an LPG system. Especially that the system makes use of OEM components – the high-pressure pump and injectors

Even after removing the plastic cover from the engine, it’s hard to figure out immediately that you see an LPG system. Especially that the system makes use of OEM components – the high-pressure pump and injectors  The largest single LPG component is the FSU module, not to be confused with an injector rail

The largest single LPG component is the FSU module, not to be confused with an injector rail  The tank has a pump whose task is to increase gas pressure – it must always remain in the liquid state

The tank has a pump whose task is to increase gas pressure – it must always remain in the liquid state  The autogas system's manufacturer provided some space in the trunk for filling adapters – now you can travel across the whole Europe in your Cee’d!

The autogas system's manufacturer provided some space in the trunk for filling adapters – now you can travel across the whole Europe in your Cee’d!  Filling up the car with liquid state gas injection system is no different from filling a tank in any other LPG car

Filling up the car with liquid state gas injection system is no different from filling a tank in any other LPG car  The trunk floor was not raised across the width – there’s a small deeper storage on the left side. It’s also better to replace the spare tire with a repair kit

The trunk floor was not raised across the width – there’s a small deeper storage on the left side. It’s also better to replace the spare tire with a repair kit

fot. gazeo.plVialle made sure that Cee’d – as a show car, the Dutch company’s flagship – does not slip by anonymously

fot. gazeo.plVialle made sure that Cee’d – as a show car, the Dutch company’s flagship – does not slip by anonymouslyIt won’t be a big overstatement to say that Vialle's LPdi system is truly revolutionary. Even those who have driven LPG vehicles for 20 years will feel quite confused once they take a look under the bonnet. OK, so there’s an ECU and something that looks like a suspiciously big injection rail with five coils instead of four, but where the hell is the reducer? Well, there isn’t one, because it’s not needed and the module that looks like a rail in a brass casing turns out to be the FSU (Fuel Selector Unit) – a unit responsible for switching between gas and petrol supply. This gas system also includes… petrol injectors and a slightly modified high-pressure petrol pump!

The simplicity is what makes the LPdi so interesting. The number of additional components is minimal. And why would we need more if we can use the original engine equipment even for gas systems? It works like this: liquefied gas is pressed from the tank by a pump installed on the tank (to make sure fuel does not vaporize in fuel lines, it is necessary to keep the pressure at a high level) and goes to the FSU module placed in the engine bay. Two additional pumps placed there ensure the pressure is kept at the right level and the unit controls the inflow of petrol or LPG through a system of solenoid valves. The fuel then goes to the OEM high-pressure pump, and further to the injectors placed directly in the combustion chambers.

© gazeo.comGas systems usually look alike. This setup looks like nothing else – you’d waste your time looking for a reducer or an injection rail

© gazeo.comGas systems usually look alike. This setup looks like nothing else – you’d waste your time looking for a reducer or an injection railThanks to using original injectors (many gas injection systems used in direct petrol injection engines work like MPI systems – gas is injected indirectly, to the intake manifold, and a certain amount of base fuel must go periodically through the injectors in order to cool them down), we don’t need any additional petrol injections. To be honest, the engine may as well start on LP gas, and you will only need traditional fuel as back-up. It’s worth using from time to time even if you don’t really need to, just so that it doesn’t stay in the tank for too long (water might separate and harmful components will precipitate).

When the rare situation occurs that we have to switch from LPG to petrol, the “ rite of passage” takes a couple of minutes. It’s because petrol has much lower pressure than LPG when it flows between FSU and the high-pressure pump. The process of lowering pressure is gradual and involves allowing small amounts of petrol into the gas-filled system. For a certain time, combustion chambers are supplied with both kinds of fuel and its excess goes through a check valve into FSU. The amount of petrol in the system grows gradually and finally the car switches to petrol-only supply. It’s much easier the other way round – gas, having higher pressure, “pushes” petrol out of the system and it takes only a short while for the engine to switch to LPG.

© gazeo.comThe unusual design of the tank forced the producer to raise the boot floor, but the operation was done solidly and aesthetically

© gazeo.comThe unusual design of the tank forced the producer to raise the boot floor, but the operation was done solidly and aestheticallyLiquid gas injection obviously has its advantages. Low fuel temperature helps overcome the everpresent problem of LPG vehicles – partial loss of power. And let’s make it clear one more time – it’s not caused by low energy value of liquefied gas, but by its physical properties. LPG has a higher energy content in a unit of mass than petrol, but because of its physical density (or rather the lack of it), it takes up more space. Pumping the amount of vaporized gas that would equal the energy level of petrol to the combustion chamber would result in an excessive enrichment of air-fuel blend, because there would be no place for air, and the engine would simply choke (there would be enough gas in terms of its mass, but too much when it comes to its volume). But let’s go back to the topic. Thanks to low temperature and high pressure (the high-pressure pump pushes fuel compressed to even 150 bars), it’s possible to pump in the amount of gas that will have as much energy as the dose of petrol. At least in theory, because our tests of Kia Cee’d 1,6 GDI with LPdi at the testbench revealed a slight drop in power anyway – around 134 PS on petrol and 130 on gas, so similar to vapour state gas injection systems. In both cases, the results are slightly worse than promised by the manufacturer (135 PS). While running on petrol, the car achieved the declared torque (164 Nm), but it was 3 Nm lower on gas. It may be nothing, but those who produce those systems always talk about additional power, so we’re a bit disappointed.

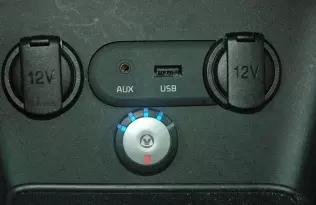

© gazeo.comThis is the fuel type switch. Take a look, for you won’t see it too much, even in your own LPdi car. Unless you reach for the 12V/AUX/USB slots

© gazeo.comThis is the fuel type switch. Take a look, for you won’t see it too much, even in your own LPdi car. Unless you reach for the 12V/AUX/USB slotsAnd what about lower gas consumption that was supposed to characterize engines converted with systems of liquid state gas injection? Those in favour of this solution (which is very good, by the way – injecting liquid fuel either to the manifold or to the combustion chamber effectively cools the head and valve system, extending their service life without the need for lubrication) often bring it up, but let’s rely on good old physics. Since thanks to low temperature and high pressure we are supposed to obtain the amount of LPG that will catch up with petrol in terms of energy, we need to have more liquid than vaporized gas (calculated by mass), so consumption will not only not go down, but will even go up. Unless we focus on providing the engine with the same amount of energy as if it was working on a vapour state injection system, and instead we choose more efficient combustion (more oxygen in the blend). As for the Cee’d LPdi, our stint with the car was too short to say anything about fuel consumption. The trip computer showed 9 l of petrol/100 km (despite the ISG – Idle Stop & Go – system operating efficiently) while driving through a congested city, so even if it went up to 11 l of gas, it would still be quite good. Especially that petrol consumption is a complete abstraction with this car.

© gazeo.comIf not for the box with gas system fuses, an untrained eye might not notice its presence in the engine bay

© gazeo.comIf not for the box with gas system fuses, an untrained eye might not notice its presence in the engine bayThere’s still one big “but”, namely the price. The LPdi system costs 2000 euros. A lot? Probably, but it’s worth looking at it from a different point of view: one would have to pay some 1150 euros more than for a Cee’d 1,6 GDI to have a Diesel engine car with comparable power, and if so, “throwing in” the sum that corresponds to the price for a fourth-generation MPI engine (i.e. the remaining 850 euros) seems much more acceptable. That’s not all – the LPdi system is virtually maintenance-free (for the sake of your own peace, it’s worth visiting service center every 50000 km, but there are no filters under the hood that would require regular replacement) and it doesn’t need a single drop of petrol to start. When you get used to the characteristic noise of the pump placed on the tank, you can easily forget you are in a liquid state LPG injection car. With time, similar solutions will surely become more common and cheaper, but even today they have their strong advocates, ready to pay more in order to save more with almost no maintenance. That’s a “yes” from us.

We'd like to thank LTA Polonia – Vialle’s distributor in Poland – for lending us the car.

Zobacz stronę producenta:

VialleYou may also find these interesting:

loading results...

loading results...