- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

Autogas tanks - safety first

loading results...

loading results...Tightness test

Each and every LPG tank coming from the assembly line is subject to a hydraulic test under 3 MPa pressure. During the test, the tank is filled with water at 3 MPa. Once the test is complete, the tank must not show signs of deformation or tightness loss.

Fire test

The test is conducted to determine whether or not a tank (complete with fittings) will burst under strictly defined fire conditions. The tank used for the test is fully equipped with fittings (a multivalve or separate valves) and placed on a fire source burning at a specified temperature (which is monitored during the test). Temperature of the tank walls is also measured (at the bottom, top and around the safety valve). Excess pressure is constantly controlled and the test lasts until pressure drops to regular levels.

Inertia

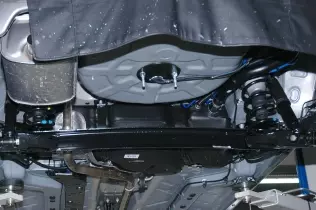

Apart from internal pressure the tank is subject to inertia, which is generated when the vehicle is on the move (accelerating, braking and tackling curves). Considering the fact that the LPG tank is the heaviest component of the autogas system (it weighs several tens of kilograms), the forces it must withstand are quite substantial, particularly during collisions, when overload rates reach extreme levels.

This is why the 67 R01 EEC UN regulation pays much attention to the matter of tank fixing. It is a crucial issue in terms of tank safety, even though it's often marginalised in the conversion process. For instance, if a tank features fixing parts welded to the outside walls, the welding seams of those parts must withstand forces of up to 30 g in every direction. Bolts and nuts used for fixing tanks to the body of the vehicle are equally important. They also must withstand overloads specified in the regulation. For vehicles with gross weight up to 3,5 tonnes, it's 20 g longitudinally and 8 g transversely. Practically speaking, if the tank weighs 50 kg, its fixings must withstand an overload of 1000 kg longitudinally and 400 kg transversely. Providing this kind of endurance requires making certain calculations and using appropriate nuts, with 8.8 toughness class.

Forces affecting the tank, particularly during a collision, when the car decelerates abruptly having hit an obstacle, can be truly extreme. This is exactly why fixing the tank properly is so important. You will be able to observe that in the material we gathered by conducting (with our partners) a crash test of autogas-powered cars. Stay tuned for more!

Zobacz stronę producenta:

STAG