- Main page

- Search

- Up to date

- Products

- Technology

- Vehicles

- Video

- Conversion Payback Simulator

Port Injection - Conversion Payback Simulator

Direct Injection - Conversion Payback Simulator

Diesel - Newsletter

- Home page

- Up to date

- Reportages, interviews, road tests

- Reportages and interviews

- App Studio - an engineer's approach

« Powrót

loading results...

loading results... © gazeo.pl

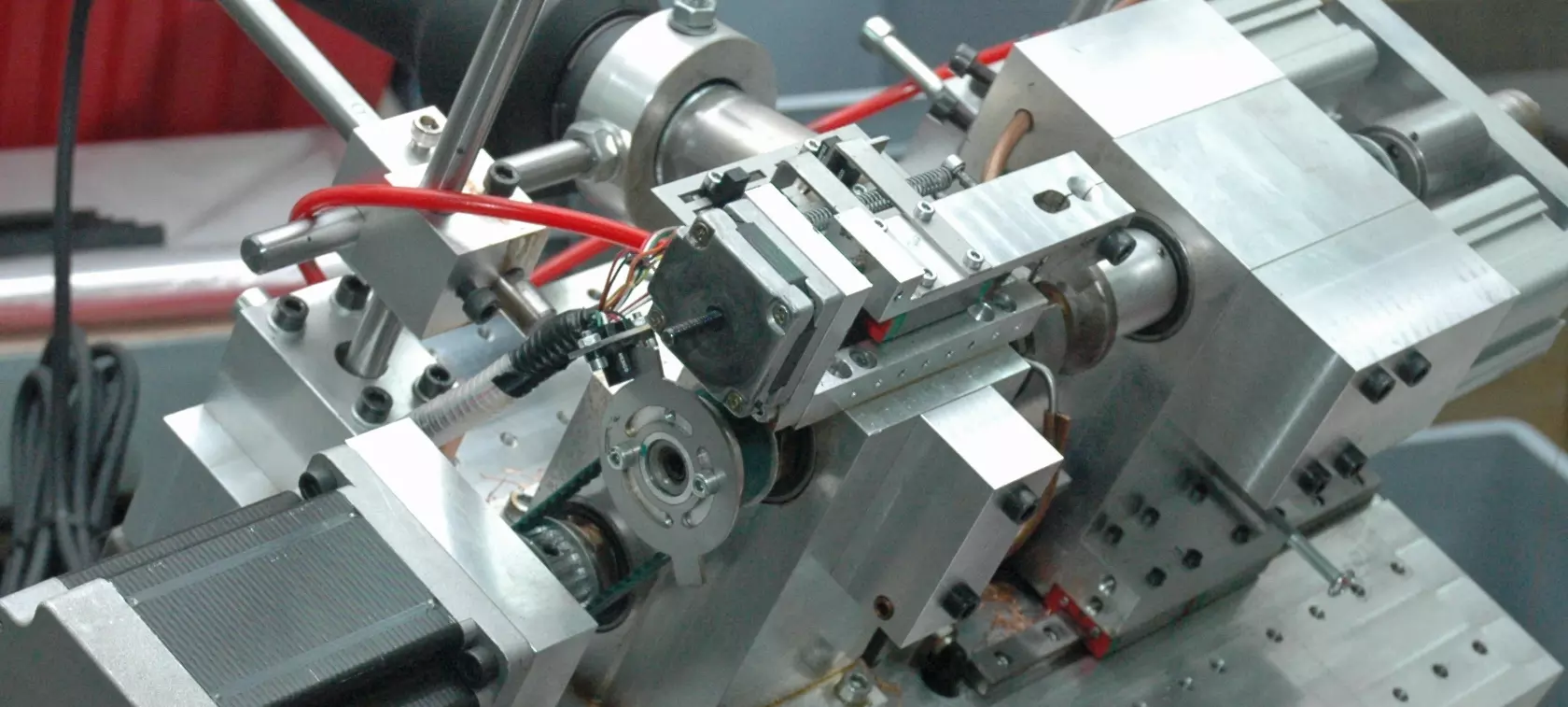

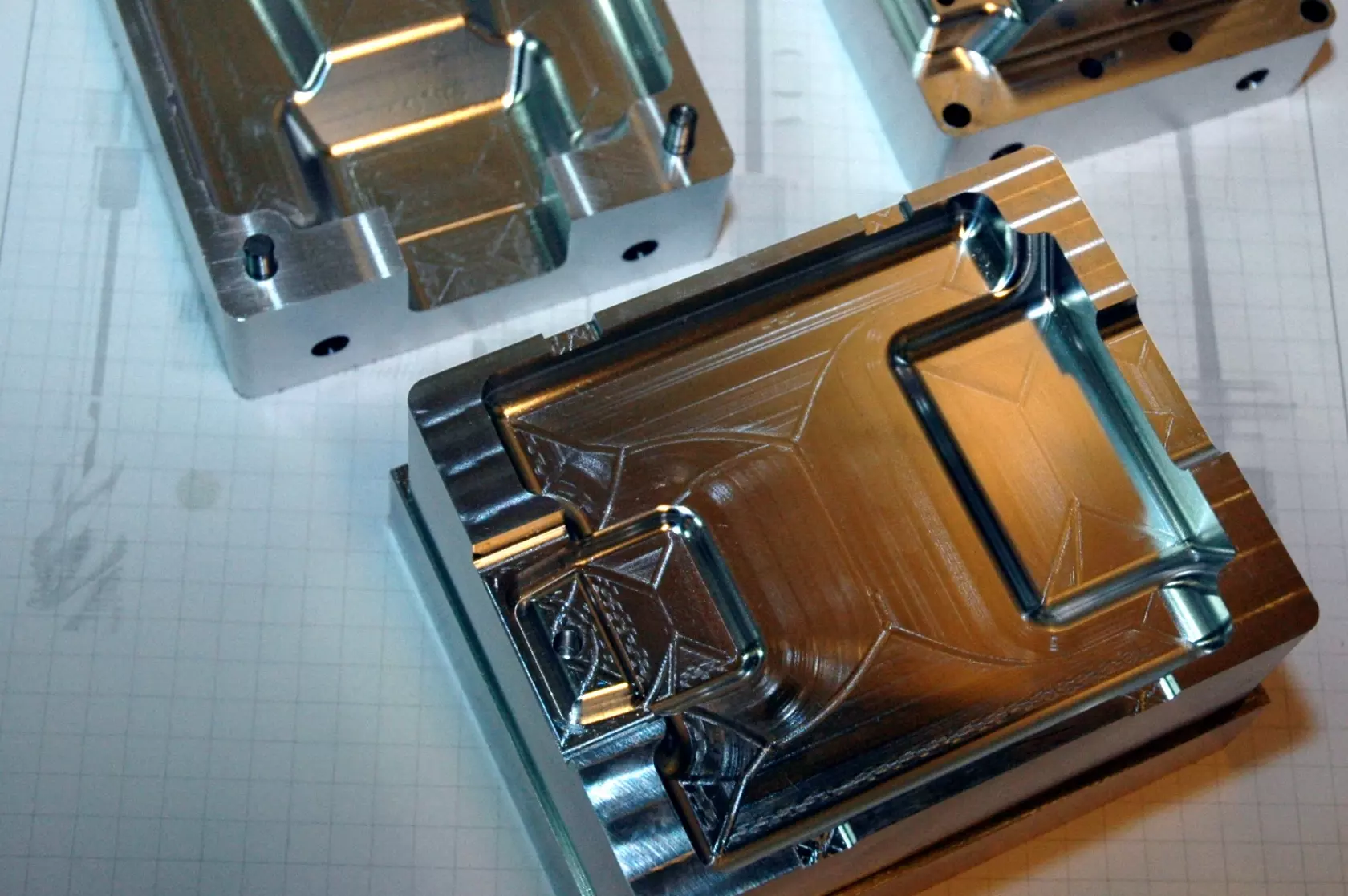

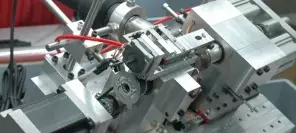

© gazeo.pl  App Studio's machine park allows the company to produce most parts and components on the spot

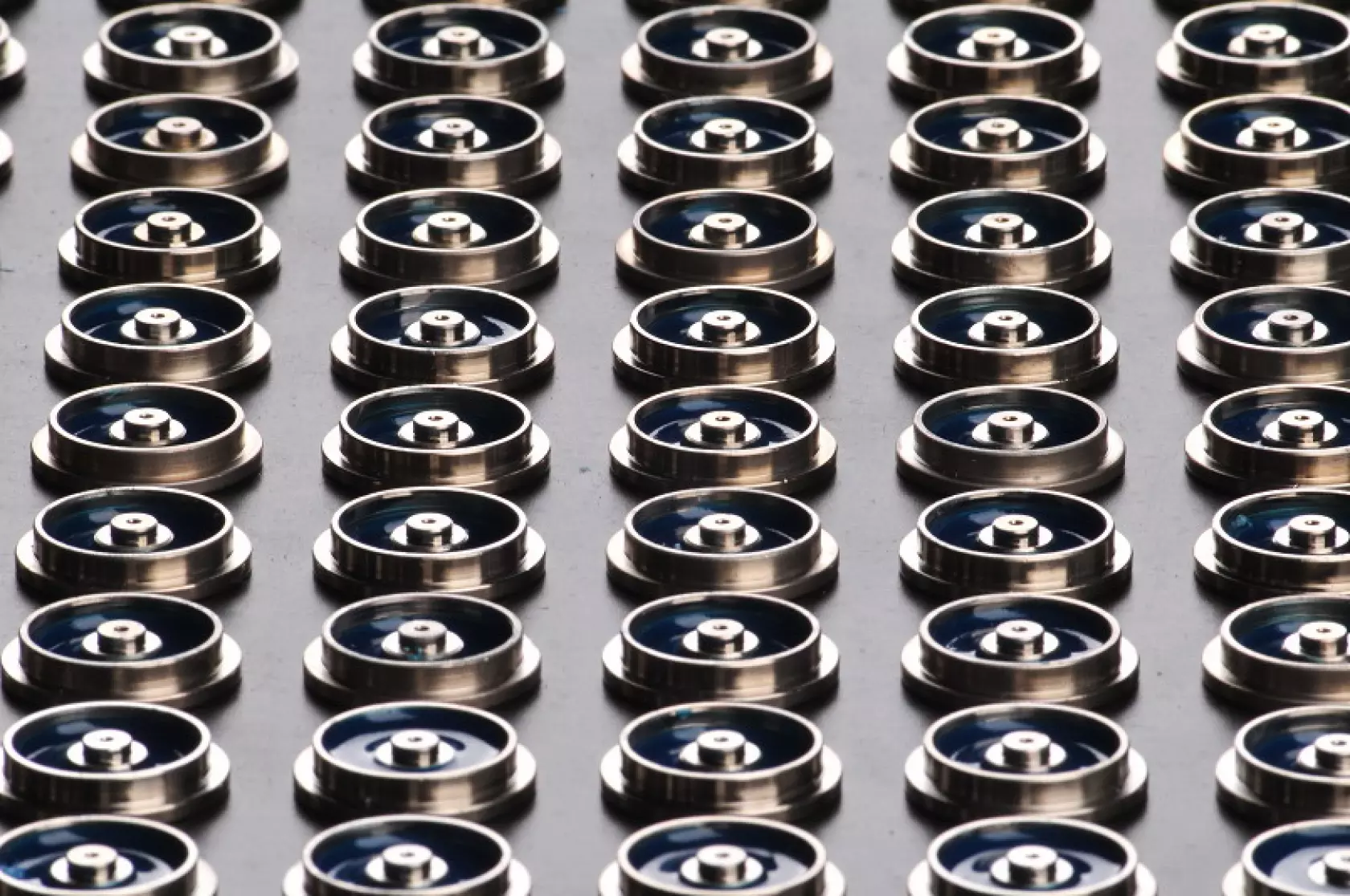

App Studio's machine park allows the company to produce most parts and components on the spot  Coils in injector bodies

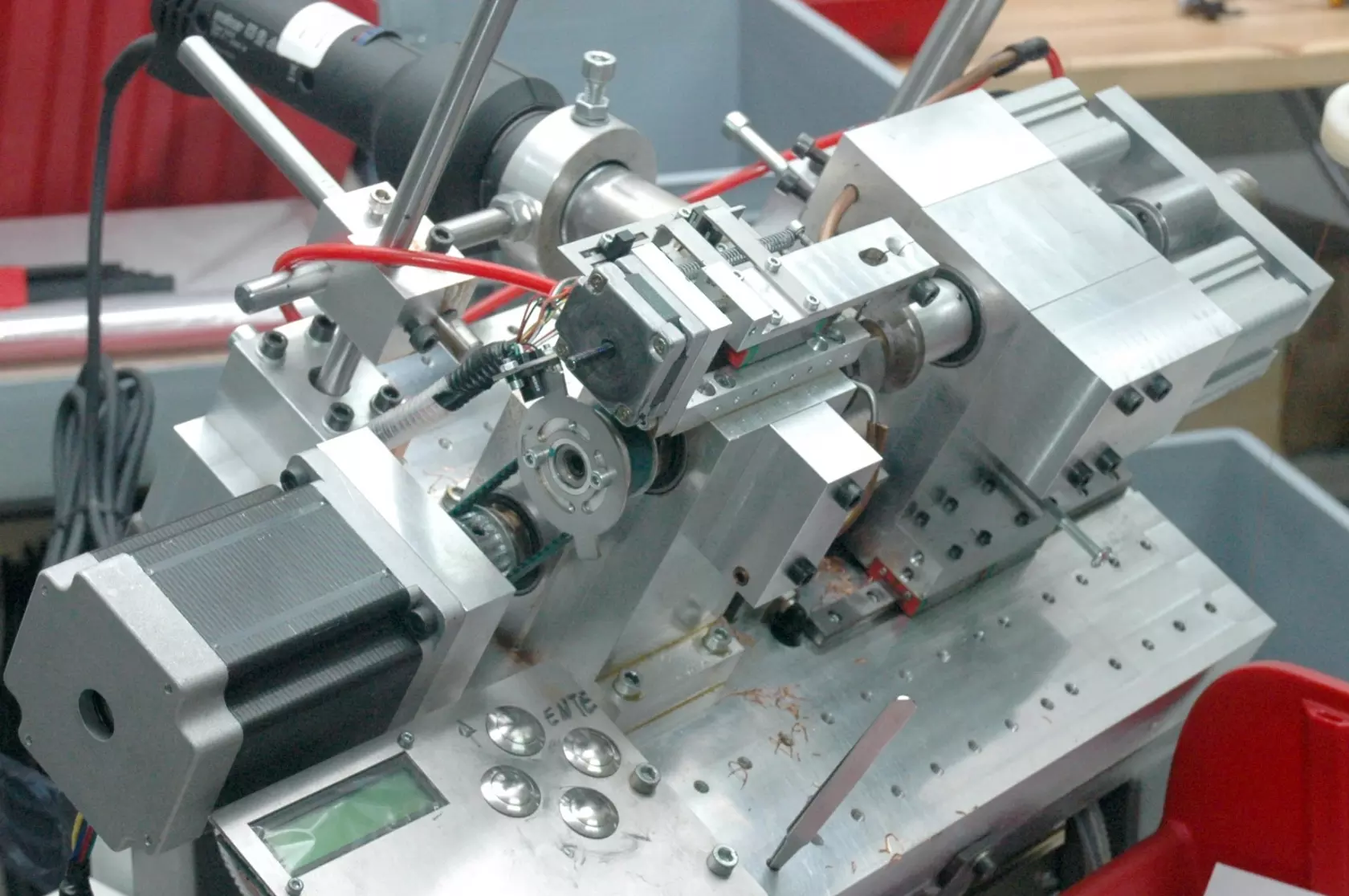

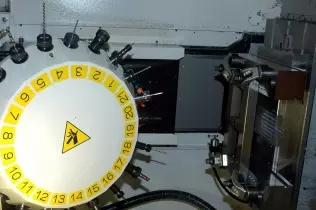

Coils in injector bodies  This coil winding machine has also been designed and built at App Studio

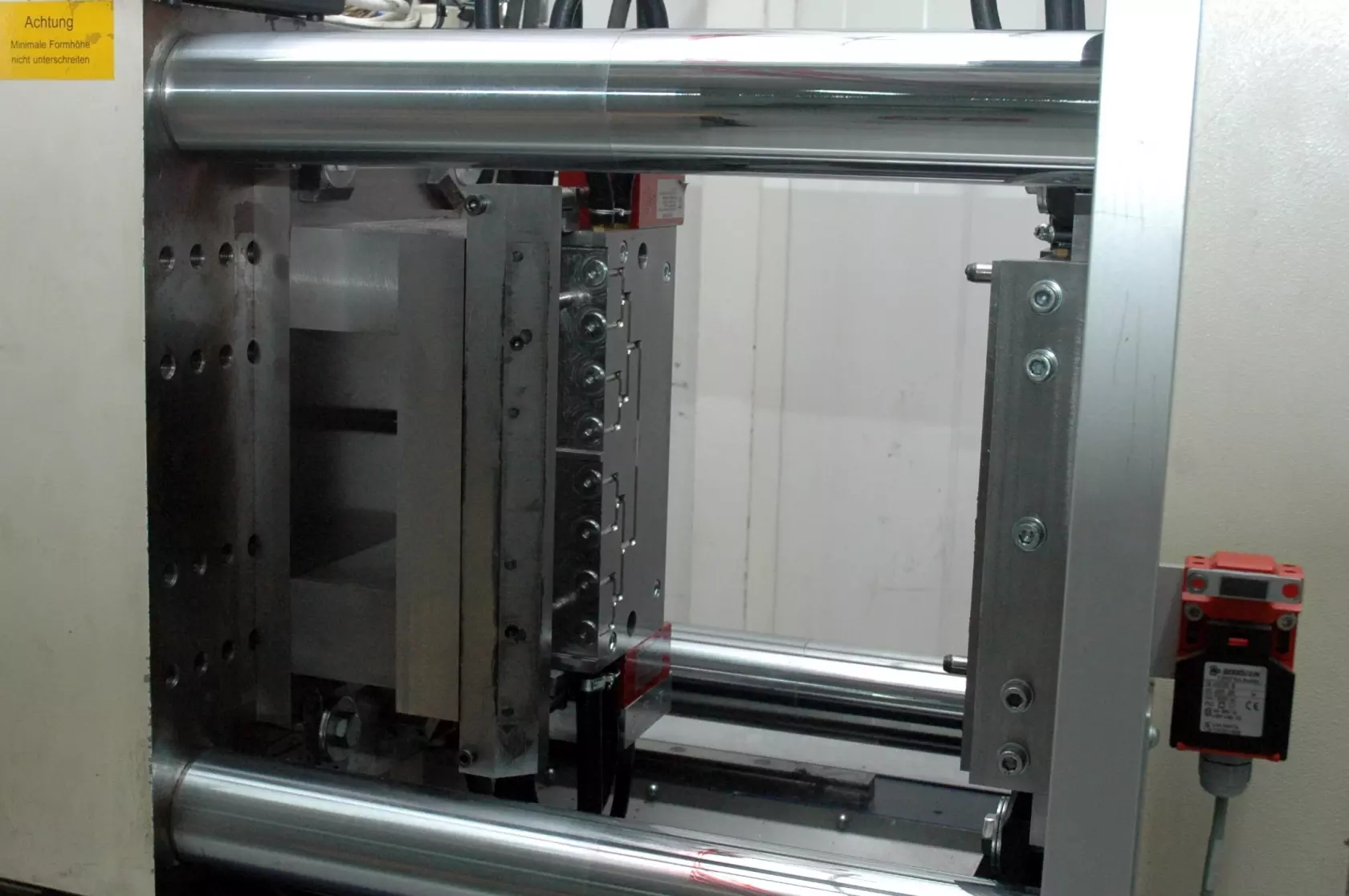

This coil winding machine has also been designed and built at App Studio  The injection moulding machine is used for producing plastic elements for injectors

The injection moulding machine is used for producing plastic elements for injectors

Experience gained during the industrial controllers manufacture and programming era proved priceless in the new branch of business.

© gazeo.comOne of the three circuit board assembly lines. The boards are first covered with soldering paste, next SMD elements are applied (for surface installation). The machine draws them from tapes rolled onto the reel visible on the right

© gazeo.comOne of the three circuit board assembly lines. The boards are first covered with soldering paste, next SMD elements are applied (for surface installation). The machine draws them from tapes rolled onto the reel visible on the rightA branch that the company would not have entered had it not been for a car of one of App Studio's owners being converted to run on autogas. It was sometime around 2003/2004, when the market for Polish-made autogas systems was only in its initial stages and there was just a single locally manufactured LPG ECU available. App Studio decided to use its expertise in the field of designing and programming of electronic control devices and develop their own autogas system control unit. The idea came into being as the Eureka, which lasted in production for approximately one year. Interestingly enough, there is another Eureka ECU available on the market today, but, apart from the name as such, it has nothing to do with App Studio.

In 2005, App Studio created the Agis brand name, by which all of the company's ECU's have since been going. The Agis line has evolved steadily, which is necessary in order to keep up with petrol engine technology development. Each generation of the Agis control unit receives new and useful functions and options, often introduced at the suggestion of users (i. e. installers).

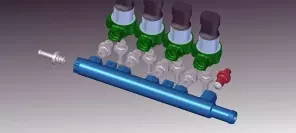

Three years after the original debut, in 2008, the Agis OBD CAN was launched. By using data from the OBD system, it adapts to changing conditions in real time, while driving. It was also in 2008 that new Apis injector rails debuted and the following year two more products were introduced: the single Apis injector and the highly efficient Ares reducer.

As of 2012, more premieres are coming, including new versions of the Agis (including a diesel-gas variant), developed on the new technological basis with a faster processor. New injectors are also in the pipeline. Their construction will take into account extreme driving conditions, such as during the winter.

Unlike today, these new injectors will be sold under the brand name Agis, which evokes clear associations with App Studio.

© gazeo.comMachining centres are used for manufacturing certain elements as well as for preparation of specialised tooling

© gazeo.comMachining centres are used for manufacturing certain elements as well as for preparation of specialised toolingAll App Studio's designs are developed internally and benefit from knowledge and experience as well as the use of latest CAD/CAM software. Production takes place in a facility in Piaseczno. Cutting-edge shaping machinery and digitally controlled assembly lines are utilised in the process and as much as possible is automated. All this, together with specialised and precise machinery, guarantees higher production efficiency, but also repeatability and high quality. It also helps to minimise the faulty human factor, responsible for most of the occuring manufacturing errors. The most automated processes inlude: production of Ares reducers (built at 5 shaping machine clusters), circuit boards (3 automated lines capable of assembling 1000 units each), programming and testing complete ECU's coming from the lines. All these processes are supervised by single people.

Finally, there comes quality control, which is an important stage. Every unit manufactured is thoroughly tested with the use of electronic equipment designed, developed and made by App Studio's engineers.

Across the 15 years of operation, App Studio has evolved from a one-man company into an important autogas components manufacturer who has experienced staff and proper machinery at disposal, let alone the 1500-square-meter headquarters. Annual production output has been doubling for the past few years running, with more than 90% of it being exported.

Zobacz stronę producenta:

APPYou may also find these interesting:

loading results...

loading results...